Plankwalker

Petty Officer 3rd Class

- Joined

- Sep 28, 2020

- Messages

- 79

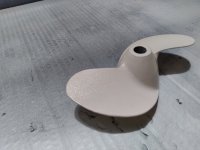

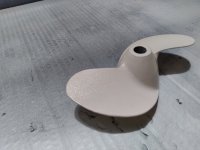

Paint anxiety

You can see in the photo how the clear coat paint is causing the paint underneath to wrinkle. I am going to try a different brand to see if it makes a difference. in then mean time, I will strip the paint off this propeller yet again. Check out the entire restoration here: Garage Sanctuary - YouTube

Some of my previous links to specific videos may not work, as I had to repost some videos. my bad.

You can see in the photo how the clear coat paint is causing the paint underneath to wrinkle. I am going to try a different brand to see if it makes a difference. in then mean time, I will strip the paint off this propeller yet again. Check out the entire restoration here: Garage Sanctuary - YouTube

Some of my previous links to specific videos may not work, as I had to repost some videos. my bad.