Day two, lots of heat, large pry bars, pb blaster, and the head won't budge?

Am I missing something here? I've applied enough force under the tabs of the head to break it in two but it won't budge.

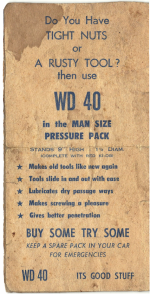

If its glued on somehow, its likely not coming off anytime soon by the looks of things After sitting soaking in hot penetrating oil overnight, and being heated with a torch for an hour I've gained no ground on getting the head to break free of the block or gasket.

I'm getting close to just running a hole saw through the face of the head to just salvage the rods and pistons and throwing the whole powe head in the scrap pile. If I use any more force than I've been using, there likely won't be anything left anyhow. If a 10 ton hydraulic spreader won't separate the head from the block, there's likely not much that will.

Not really related to my original post here but I've got a half dozen Stihl chainsaws and every one of them uses a felt air filter, so does my old Homelight. The Stihl saws use a felt covered screen, the Homelite has a stiff felt filter in the shape of the side cover opening. The Stihl saws are fairly new, all from the 90's or 00's, the Homelite is mid 60's.

I don't think I've ever seen a saw with a foam filter.

This fits my 036 Pro, and my 024, 026, 029, 034, & 056 use the same or similar filters. My Stihl concrete saw uses a round paper element.

Am I missing something here? I've applied enough force under the tabs of the head to break it in two but it won't budge.

If its glued on somehow, its likely not coming off anytime soon by the looks of things After sitting soaking in hot penetrating oil overnight, and being heated with a torch for an hour I've gained no ground on getting the head to break free of the block or gasket.

I'm getting close to just running a hole saw through the face of the head to just salvage the rods and pistons and throwing the whole powe head in the scrap pile. If I use any more force than I've been using, there likely won't be anything left anyhow. If a 10 ton hydraulic spreader won't separate the head from the block, there's likely not much that will.

Not really related to my original post here but I've got a half dozen Stihl chainsaws and every one of them uses a felt air filter, so does my old Homelight. The Stihl saws use a felt covered screen, the Homelite has a stiff felt filter in the shape of the side cover opening. The Stihl saws are fairly new, all from the 90's or 00's, the Homelite is mid 60's.

I don't think I've ever seen a saw with a foam filter.

This fits my 036 Pro, and my 024, 026, 029, 034, & 056 use the same or similar filters. My Stihl concrete saw uses a round paper element.