BioChemLab

Cadet

- Joined

- Jun 14, 2021

- Messages

- 12

Hey guys,

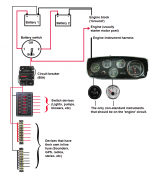

So after my engine swap and break-in, the boat is running great, apart from some strange electrical issues.

Every now and then (usually when the bilge blower is on...) some of the gauges will max out and stick there - sometimes toggling the bilge blower on/off will fix it, sometimes it won't. While checking for good grounds today, I noticed that with the bilge blower on (and the engine off, not in the water, etc) the note of the blower changes every now and then. It seems to be getting an intermittent bad ground - or something along those lines, and I'm not sure what to do next.

I've verified good low impedance ground on all of the connections on the back side of the helm plate, and I've unplugged and replugged every connector I can find, checking for corrosion and such, and found nothing. I've also unplugged all the other aftermarket stuff I've added (light bar, aftermarket stereo, amp etc) to make sure none of that is causing an issue. So far, nothing has changed.

I did notice when I was putting the engine back together that I guess at some point I smacked the oil pressure sensor (the three-wire one down by the oil filter), it looks like just the plastic that cracked but messing with that plug seems to sometimes rectify the problem, but I can't be sure if that's coincidence or has something to do with it. I can't imagine that the ground for the entire switch panel/helm runs through the oil pressure switch - right...?

Thanks.

Jon

So after my engine swap and break-in, the boat is running great, apart from some strange electrical issues.

Every now and then (usually when the bilge blower is on...) some of the gauges will max out and stick there - sometimes toggling the bilge blower on/off will fix it, sometimes it won't. While checking for good grounds today, I noticed that with the bilge blower on (and the engine off, not in the water, etc) the note of the blower changes every now and then. It seems to be getting an intermittent bad ground - or something along those lines, and I'm not sure what to do next.

I've verified good low impedance ground on all of the connections on the back side of the helm plate, and I've unplugged and replugged every connector I can find, checking for corrosion and such, and found nothing. I've also unplugged all the other aftermarket stuff I've added (light bar, aftermarket stereo, amp etc) to make sure none of that is causing an issue. So far, nothing has changed.

I did notice when I was putting the engine back together that I guess at some point I smacked the oil pressure sensor (the three-wire one down by the oil filter), it looks like just the plastic that cracked but messing with that plug seems to sometimes rectify the problem, but I can't be sure if that's coincidence or has something to do with it. I can't imagine that the ground for the entire switch panel/helm runs through the oil pressure switch - right...?

Thanks.

Jon