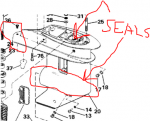

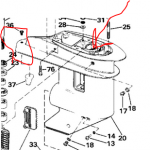

Trolling for stripers at dawn, ran over an abandoned partly submerged crab pot with my 25 HP Evinrude E25ELEID (1991) which has been like a good friend. The prop was chewed up a bit and tangled with the line, but son was able to remove it and motor restarted. Bad part is that it broke off a large chunk of the anti-cavitation plate. And that chunk had the anode which also serves as a trim tab to counter the torque from the prop rotation. So, now the boat (16 foot Alumacraft) pulls to the right, esp at WOT. It still goes almost 30 mph with two adults and lots of gear, but having to steer (remote) constantly is a new distraction. Need advice: is it worth removing the LU and getting someone very talented to weld on a piece of aluminum plate? Have heard the heat can ruin the seals but have no experience with that. Or, is it possible to bolt on an ugly aftermarket plate and attach the anode to it? Or should I look for a used LU to replace the entire unit? Or can I mount the motor at an angle and find another place for the anode? Or should I just get back to fishing and not worry about steering or electrolysis or how bad it looks? See attached photo taken from above with motor raised. Any and all advice requested.