Re: Changing transom wood

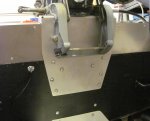

I cut the aluminum C-channel from the top, so that the sides of the C were intact, but I could slide the bad wood out the top, then slid the new wood down from the top (2 pcs of 3/4" oak planking coated in teak oil). I also converted mine from a 15" transom to a 20" by cutting the new wood longer (sticking out the slot) and used a piece of 2"x5" aluminum box channel that is normally used for storefront windows/doors to make a new crosspiece along the back of the boat. Used about 30 3/8" aluminum pop-rivets on each of the back corners of the boat tying the beam to the hull. Had a filler panel cut to provide a cover for the original stepped-down splashwell and then added a small "jackplate" that bent up and around the transom where the motor bolts on to sandwich it all together. To get my anti-cavitation plate to the right height, I made the "jackplate" about 1" higher than even with the rear corners of the boat decking. Looks a little unusual, but the boat goes 25mph now instead of 19 and still turns well without cavitation and can pull a tuber just fine.

My boat came with a rotted transom and all other wood GONE, so I've redone the floor and rigged-up a minivan rear removable seat as the main seat, we use a Cosco booster seat for my son, and a WalMart folding seat for my daughter for now. I plan to use some coolers for future seating and storage.

Hope to post and read more on this forum.

I have several of the original hardware items that I plan to sell - steering wheel, Johnson Shipmaster style ignition switch / choke bezel, may sell the shipmaster controls since my Evinrude is an "86 with OMC controls, cigarette lighter, speedo, front red/grn light, rear light w/pole, windshield hardware and more.

Darrell

1960 16 foot S169RF? (had blue duradecking, so was built in late 59, I think)