sweetwaterec

Cadet

- Joined

- Aug 12, 2012

- Messages

- 7

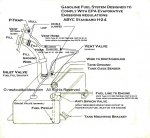

I will be installing a new aluminum fuel tank (mounts under deck to the cross members) and stainless flush mount deck fuel fill on my pontoon boat. The mfg of the fuel fill states that the filler tube should be bonded. My questsion is this; I assume I should bond the fuel fill to the tank by running a wire from the fill to the tank and then from the tank to the grounding bar that is wired to the negative side of the engine? Advice and help is certainly appreciated.

Thanks,

Stephen

Thanks,

Stephen