theorifice

Cadet

- Joined

- Feb 15, 2023

- Messages

- 29

Hi all,

First time doing work on the outdrive and noticed a few things that I'd like to get advice on. The boat is a 1987 with dual sterndrive (Carver Santego 30). I haven't a clue on the service history. The engines run great but was very hard to get into gear last year. I'm getting a bit low on time to get the boat ready for launch and looking to do just enough to get through the season without catastrophe. Expecting to

Initial inspection of shift cables by removing lower shift cable from bracket and shifting by hand showed high friction on the port side and medium friction on the starboard side.

Plan is to pull both drives, replace shift cables and impellers, inspect gimbal bearings and all bellows.

So far I'm into the starboard side.

* Welch plug missing. I'm doing the lower shift cable anyways. Anything else I might need to look at?

* trim ram pivots nearest transom are really stiff. Do the bushings to replaced or lubricated or are they meant to be tight? Seeing other videos, it looks like the rams could move freely.

* There's some amount of metal shavings on the magnetic drain plug. Is this a reasonable amount?

* There was a lot of grease on the inside of the drive shaft bellows. It looks like orings on the shaft were missing as we pulled out. I need to confirm they're not still in channel.

* Scoring on lower drive shaft near the water pump and near the splines

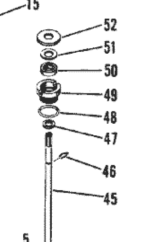

* Slight vibration when turning the lower shaft by hand. There is some end play and if I take up the end by pulling on the shaft, the vibration goes mostly away. (

)

* One of the waterpump bolts (nearest shift shaft) had a lot of corrosion. Is this a sign of another problem? Is it possibly due to the missing welch plug? Should I replace anything?

* The waterpump gasket was kind of fused to the waterpump. It looks like the plastic of the waterpump is slightly melted that is closest to the impeller. Is this an issue?

Thanks all!

First time doing work on the outdrive and noticed a few things that I'd like to get advice on. The boat is a 1987 with dual sterndrive (Carver Santego 30). I haven't a clue on the service history. The engines run great but was very hard to get into gear last year. I'm getting a bit low on time to get the boat ready for launch and looking to do just enough to get through the season without catastrophe. Expecting to

Initial inspection of shift cables by removing lower shift cable from bracket and shifting by hand showed high friction on the port side and medium friction on the starboard side.

Plan is to pull both drives, replace shift cables and impellers, inspect gimbal bearings and all bellows.

So far I'm into the starboard side.

* Welch plug missing. I'm doing the lower shift cable anyways. Anything else I might need to look at?

* trim ram pivots nearest transom are really stiff. Do the bushings to replaced or lubricated or are they meant to be tight? Seeing other videos, it looks like the rams could move freely.

* There's some amount of metal shavings on the magnetic drain plug. Is this a reasonable amount?

* There was a lot of grease on the inside of the drive shaft bellows. It looks like orings on the shaft were missing as we pulled out. I need to confirm they're not still in channel.

* Scoring on lower drive shaft near the water pump and near the splines

* Slight vibration when turning the lower shaft by hand. There is some end play and if I take up the end by pulling on the shaft, the vibration goes mostly away. (

* One of the waterpump bolts (nearest shift shaft) had a lot of corrosion. Is this a sign of another problem? Is it possibly due to the missing welch plug? Should I replace anything?

* The waterpump gasket was kind of fused to the waterpump. It looks like the plastic of the waterpump is slightly melted that is closest to the impeller. Is this an issue?

Thanks all!