You basically got it ... when you ordered the drive, you could order it with Selectrim or without. The 190 wasn't available until '74, but it was still electric shift. In the '74 190 you had the option of the engine mount group being fixed, or having the selectrim jackscrew in the front mount. Hydraulic trim (still the front mount) wouldn't be available until 1975.

You could probably manage to frankenstein either system together on the front mount if it all mated up, but either will be a search for no-longer-available parts to get the setup going.

Bondo's point is that while you're reworking all of the glass ... re-do the transom and put a Merc or Volvo in now. The Stringer's hole is bigger than any other sterndrive produced. Once you cut the transom for a Stringer, you have to rebuild the transom in order to convert to another driveline. Since you're already knee deep in the work ... you can more easily convert now if you want to.

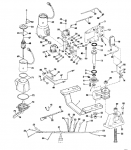

OMC went out of business in the 90s and stopped producing stern drives. The Stringer models haven't been produced since 1986, and the electric shift models were done by 1976. It's a vintage drive, a little quirky and many marine service techs have never seen one (let alone worked on one). Just be prepared that you're going to be having to care for an antique with that drive.