JohnnyGuy

Petty Officer 2nd Class

- Joined

- Aug 24, 2017

- Messages

- 192

Good afternoon all,

A couple of years ago I picked up a 1974 Evinrude 15hp E-Start that came with a 87 15hp parts motor. I have finally got around to fixing the '74 to be a runner again.

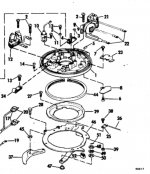

The '74 had issues with slop in the armature plate (up and down wobble) and the coils had some of their wires cut. I took the armature plate bearing (#44 in the parts breakdown photo attached) from the '87 parts motor. After I replaced the bearing it took out the up and down slop of the armature plate. But I noticed that the armature plate still moves ever so slightly every time the magnet passes the driver coil. If you watch the plate (#46) where it engages the neutral stop and you rotate the flywheel, the plate moves front to back (like you backed off of the throttle ever so slightly).

Anyone had this issue before? If so, what's the fix?

Thanks in advance.

JG

A couple of years ago I picked up a 1974 Evinrude 15hp E-Start that came with a 87 15hp parts motor. I have finally got around to fixing the '74 to be a runner again.

The '74 had issues with slop in the armature plate (up and down wobble) and the coils had some of their wires cut. I took the armature plate bearing (#44 in the parts breakdown photo attached) from the '87 parts motor. After I replaced the bearing it took out the up and down slop of the armature plate. But I noticed that the armature plate still moves ever so slightly every time the magnet passes the driver coil. If you watch the plate (#46) where it engages the neutral stop and you rotate the flywheel, the plate moves front to back (like you backed off of the throttle ever so slightly).

Anyone had this issue before? If so, what's the fix?

Thanks in advance.

JG