2008 V-P twins, type 5.0 OSi-JF. "F" as in freshwater cooled. We bought the boat late last year, and I motored about 75 miles from Great Bridge, VA, to new home in Urbanna with no problems at all. Family health issues have kept us away from the boat for most of this year; it's a 3-hour drive from home. Boat was winterized last December and summerized in June, both times by the shop at our marina. No problems with running gear noted, other than having to replace a failed alternator and all the batteries [due to failed shore power wiring, now fixed].

My first time out this year with the boat, I idled out the creek and into the Rappahannock. Within seconds of getting on plane, an alarm sounded and I noticed that the starboard temperature gauge was passing 200. Shut her down and returned on port engine only. After about 15 minutes I restarted starboard engine and idled back to slip at normal temperatures.

Marina owner suggested I check impeller, thermostat, and heat exchanger - in that order. So, on next trip to boat, I replaced impeller and t-stat with V-P parts. Old impeller had taken a set but was fully intact and showed no cracks. T-stat looked OK; it was a 170, but got replaced by a 160. This time I idled up the creek to the ski area and opened her up. Same result. After a very brief full throttle run, alarm sounded, I throttled back and checked with pyrometer: risers at 205. Other components seemed more normal, although I did not scan everything before shutting off.

Third trip I removed the heat exchanger, popped the ends, and looked through a very clean unit. Only deposit was a little pile of corroded debris below what was left of the zinc. Cleaned that out and re-assembled. Before attaching output hose from raw water pump, I briefly started the engine and observed what I think was adequate water flow.

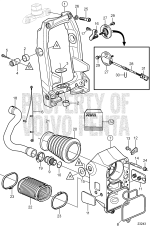

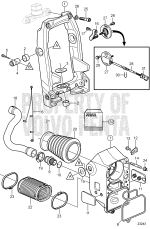

So it looks like a raw water flow problem. Unfortunately, my V-P owner's manual shows a coolant flow diagram for the non-freshwater engine only [GXi-J or OSi-J]. Before proceeding further, I would like to have a freshwater engine coolant flow diagram. From what I've read here and on THT, there is at least one cooler for oil and power steering that could be clogged and restricting flow on the raw water side. Of course I would greatly prefer to deal with a clogged cooler than r&r the risers and manifolds.

All suggestions welcomed, and please, could someone send the proper flow diagram?

tia, 686Sport

My first time out this year with the boat, I idled out the creek and into the Rappahannock. Within seconds of getting on plane, an alarm sounded and I noticed that the starboard temperature gauge was passing 200. Shut her down and returned on port engine only. After about 15 minutes I restarted starboard engine and idled back to slip at normal temperatures.

Marina owner suggested I check impeller, thermostat, and heat exchanger - in that order. So, on next trip to boat, I replaced impeller and t-stat with V-P parts. Old impeller had taken a set but was fully intact and showed no cracks. T-stat looked OK; it was a 170, but got replaced by a 160. This time I idled up the creek to the ski area and opened her up. Same result. After a very brief full throttle run, alarm sounded, I throttled back and checked with pyrometer: risers at 205. Other components seemed more normal, although I did not scan everything before shutting off.

Third trip I removed the heat exchanger, popped the ends, and looked through a very clean unit. Only deposit was a little pile of corroded debris below what was left of the zinc. Cleaned that out and re-assembled. Before attaching output hose from raw water pump, I briefly started the engine and observed what I think was adequate water flow.

So it looks like a raw water flow problem. Unfortunately, my V-P owner's manual shows a coolant flow diagram for the non-freshwater engine only [GXi-J or OSi-J]. Before proceeding further, I would like to have a freshwater engine coolant flow diagram. From what I've read here and on THT, there is at least one cooler for oil and power steering that could be clogged and restricting flow on the raw water side. Of course I would greatly prefer to deal with a clogged cooler than r&r the risers and manifolds.

All suggestions welcomed, and please, could someone send the proper flow diagram?

tia, 686Sport