Normspeed

Cadet

- Joined

- Feb 20, 2011

- Messages

- 9

I'm starting this new thread hoping this will help others. My 1984 70 hp Evinrude had the fairly common problem of running fine at idle or full throttle but bogging down and stalling when accelerating to get planed out. It would get past the flat spot if I hit the enricher by pushing in the ignition key. Like others in this forum and elsewhere, I suspected a lean condition, probably in the idle circuit, just before the high speed jets took over. Rebuilt all three carbs (twice), rebuilt, then replaced fuel pump, replaced all fuel hoses, checked fuel supply from tank, performed link n sync, checked timing ring for proper movement, and applied grease to the throttle shafts to seal up vacuum leaks. Bought a set of richer idle orifices but before I got them installed I found a reference to an old OMC service bulletin suggesting that venting the prop can help get the boat planed fast and won't alter performance in any other way.

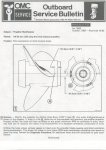

I followed the procedure which involved drilling a small hole near the base of each prop blade. The size and placement are very specific. I used my spare prop (I had the same bogging problem with both props ). Just returned from the lake and the bogging is completely gone! Switched to the unvented prop and problem came back. I'm going to vent that other prop (a brand new Solas) and I'm sure it will also get rid of the bogging. The idea of prop venting is pretty common, but I hadn't run across it in discussions of the 3 cylinder Johnson/Evinrudes with the acceleration bogging problem. I would compare the problem to shifting a standard shift car from 1st to 4th gear without using the gears in between. In my case, the Evinrude was originally on a lighter 16 foot bowrider where it probably worked fine, but my boat is heavier and needed to get rpms up quickly on takeoff, where it would bog. The venting procedure allows some limited controlled cavitation on takeoff, greatly improving hole shot and getting the rpms up quickly. Once you're on plane, the venting stops and exhaust goes out through the hub, not the vent holes. Top end performance is the same. I'm posting a picture of the TSB showing exact hole placement. If you happen to find this procedure in your Seloc manual, propeller section, beware, their illustration is not correct. They got it wrong on where to measure. I hope this helps others with this problem. My props are aluminum, easy to drill, and easy to plug the holes if you don't like the results (JB Weld). Hole shot is now really impressive and no bogging or stalling at all.

I followed the procedure which involved drilling a small hole near the base of each prop blade. The size and placement are very specific. I used my spare prop (I had the same bogging problem with both props ). Just returned from the lake and the bogging is completely gone! Switched to the unvented prop and problem came back. I'm going to vent that other prop (a brand new Solas) and I'm sure it will also get rid of the bogging. The idea of prop venting is pretty common, but I hadn't run across it in discussions of the 3 cylinder Johnson/Evinrudes with the acceleration bogging problem. I would compare the problem to shifting a standard shift car from 1st to 4th gear without using the gears in between. In my case, the Evinrude was originally on a lighter 16 foot bowrider where it probably worked fine, but my boat is heavier and needed to get rpms up quickly on takeoff, where it would bog. The venting procedure allows some limited controlled cavitation on takeoff, greatly improving hole shot and getting the rpms up quickly. Once you're on plane, the venting stops and exhaust goes out through the hub, not the vent holes. Top end performance is the same. I'm posting a picture of the TSB showing exact hole placement. If you happen to find this procedure in your Seloc manual, propeller section, beware, their illustration is not correct. They got it wrong on where to measure. I hope this helps others with this problem. My props are aluminum, easy to drill, and easy to plug the holes if you don't like the results (JB Weld). Hole shot is now really impressive and no bogging or stalling at all.

Attachments

Last edited: