Live-liner

Seaman

- Joined

- Sep 19, 2012

- Messages

- 74

Good Morning all,

Just looking for a bit of input.

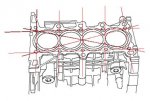

I just replaced the head gasket on my 1986 3.7 190. This is what the deck looked like upon disassembly. My compression test came out as; #1-155, #2-150, #3-125, and #4-135. Couldn't get the boat to idle and saw some steam and loss of coolant, hydro-lock (hard starting), etc. Prompted me to replace manifold and elbow. Put it all back together and still had issues, took head off and replaced head gasket.

This is what the srface looked like, note the dark areas around the front of #3 and #4, also dark areas on the sleeves of both cylinders, also lots of crud on piston #4. Can I assume that there was definately a leak in those areas? I did clean everything up befor re-assembly. ad cleaned the head and valve surfaces where there was actually light rust (no carbon)

There was no etching or anything on the surfaces, everything cleaned up nice. I will finish getting it back together this weekend and retorque the head after warm up.

Thank you in advance for your input. I have been dealing with the issues associated with this motor for the last three years before stumbling upon this forum. I wish I would have looked it up earlier!

Just looking for a bit of input.

I just replaced the head gasket on my 1986 3.7 190. This is what the deck looked like upon disassembly. My compression test came out as; #1-155, #2-150, #3-125, and #4-135. Couldn't get the boat to idle and saw some steam and loss of coolant, hydro-lock (hard starting), etc. Prompted me to replace manifold and elbow. Put it all back together and still had issues, took head off and replaced head gasket.

This is what the srface looked like, note the dark areas around the front of #3 and #4, also dark areas on the sleeves of both cylinders, also lots of crud on piston #4. Can I assume that there was definately a leak in those areas? I did clean everything up befor re-assembly. ad cleaned the head and valve surfaces where there was actually light rust (no carbon)

There was no etching or anything on the surfaces, everything cleaned up nice. I will finish getting it back together this weekend and retorque the head after warm up.

Thank you in advance for your input. I have been dealing with the issues associated with this motor for the last three years before stumbling upon this forum. I wish I would have looked it up earlier!