benfish909

Petty Officer 2nd Class

- Joined

- Jan 4, 2021

- Messages

- 122

Hi everyone,

I am in the process of doing a rebuild on my 21' Holiday. Paperwork say 1969 but I think it looks like a 1972. The plan is to replace transom, floor, side panels, and all new wiring. Everything has been pulled out and hull has been pressure washed. Found a couple rivets to replace then gluvit for a little insurance. Hand to pull the stringers because they were screwed in with galvanized self-tappers. The floor was 2 layers of treated 3/4'' which will be replace with 1 layer of epoxied 3/4" non-treated.

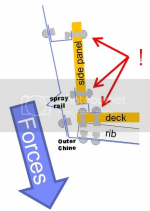

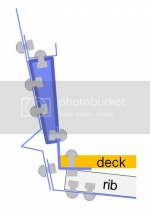

My current question is when re-riveting the strings to the ribs, should you add a bit of silicone or some type of rubberized tape to help with vibration? or would this make it worse.

The bottom layer on the bow appeared to be original

Rough cut on the transom, it has been shaped and ready to fit but didn't get a pic.

All clean and ready for rivet replacement

I am in the process of doing a rebuild on my 21' Holiday. Paperwork say 1969 but I think it looks like a 1972. The plan is to replace transom, floor, side panels, and all new wiring. Everything has been pulled out and hull has been pressure washed. Found a couple rivets to replace then gluvit for a little insurance. Hand to pull the stringers because they were screwed in with galvanized self-tappers. The floor was 2 layers of treated 3/4'' which will be replace with 1 layer of epoxied 3/4" non-treated.

My current question is when re-riveting the strings to the ribs, should you add a bit of silicone or some type of rubberized tape to help with vibration? or would this make it worse.

The bottom layer on the bow appeared to be original

Rough cut on the transom, it has been shaped and ready to fit but didn't get a pic.

All clean and ready for rivet replacement