2004 searay

Seaman Apprentice

- Joined

- Jun 30, 2023

- Messages

- 30

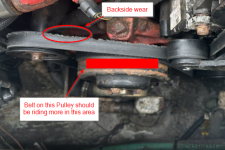

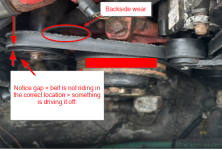

as the title says, the belt jumped inwrad towards the engine and tore 1 rib off it. i read about someone who hadthe bracket for the alternator/p.s pump fatigured and bent but this engine already has the cast aluminum bracket. i replaced this belt last spring(2023) due to squeeling, replacedwith a v/p belt. also replaced both idler and tension pulleys. the crank pulley was replaced with the pump about 3 years ago and is still shiney and new looking. the p/s puley was replaced 3 years ago when the engine was pulled out to repair an oil leak, the pulley was very crusty. the alternator was replaced 4 years ago. the only original pulley on the engine was the circulator pump pulley which i just purchased to install with another new v/p belt. i need to resolve this issue before it occurs again and i am not sure what direction to head to now.