Apologies if I wasn't clear..........I assume some think as twisted as I do

The problem here with merc's in this area is.........yes, it's bonded as Duke and I have indicated via this wire but,

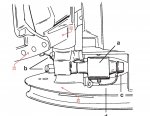

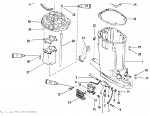

The trim gauge's high side/signal wire is connected to the trim sender, so the sender mounted on the tilt/steering plate has voltage hooked to it via this wire, pretty simple so far so good...........Therefore it will/can have some current (milliamps, its current limited via the gauge's design) running through it back to its ground/return path.

Merc here however pulled a fast one and also uses the bonding (grounding) of the tilt/steering plate as the senders ground/return path via a mounting screw/ring lug arrangement AND your now broken wire.

Using bonding wires to carry current is a big no no for best practice bonding as this is a prime example of why it shouldn't be done...

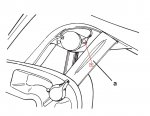

YOUR wire to this tilt plate is now broken and the sender's current now will look for a ground path back to its source using whatever path it can find......This spells trouble and with salts, acidity and bases that are dissolved in water. The more, the better the electrolyte becomes, the more current can flow, the more metal can move.

I'd guess your Zinc, if conditions are fair, could be gone within month or two with a 10'ish ma. leak.

Corrosion will now rapidly consume things more so then just the weak battery form of **natural galvanic corrosion**. This, unlike the natural galvanic corrosion in dissimilar metals in water, this is direct current leakage which is far faster at eating things.

The current will seek the closest ground, hopefully this will be your bonded (grounded) lowest noble metal, your "Zinc". The Zinc/Al. will still be used as the sacrificially anode (as always being the most noble we have/use), but with now with a newly created cathode being made with trim/steering plate.

The current path will be from the highest noble metal, most likely being an unpainted stainless steel component in your tilt/steering assembly (bearing race, trim ram, etc.). When the Zinc is gone however, it's a crap shoot which goes next as you can guess. Theory says the next higher in line noble I reckon, which ever bit on your boat/motor that would be.

You can remove the power to the trim gauge as a work around but, since the bonding wire remains broken, you will still have un-bonded (floating) metal.

**Metals dissimilar suffer from the above mentioned natural galvanic corrosion because ionically dissimilar metals can form ever so slight potential differences between them and with an electrolyte present, small current flows between the metals, slowly carrying one metal to and depositing it on the other (corrosion). If the metals in questions are hard wired together (bonded), this prevents a "potential difference" from forming, no potential difference, no current flow, no corrosion.........Magic!!

You could however replace the $5.00 wire, just say'n.

**********The opinions expressed here are the views of the author and do not reflect the views and opinions of any employer or customer of the author. While every effort is made to ensure that the content is accurate, the opinion is provided ?as is? and I make no representations or warranties in relation to the accuracy or completeness of the information found on it. While the content of my opinion is provided in good faith, I do not warrant that the information will be kept up to date, be true and not misleading, or that this site will always (or ever) be available for use.********

This has been a recording............