xBoomhauer

Cadet

- Joined

- May 12, 2023

- Messages

- 17

Long story short, picked up a Tracker Guide V14 with a 1984 Johnson 35hp 2 cylinder 2-stroke (J35RLCRR). The low speed needle retaining ring had disintegrated, so while I was replacing that I went ahead and removed/cleaned/rebuilt the carb. Now I have everything back together and am trying to get everything synced/adjusted properly.

I am referencing the OMC manual as well as Seloc manual 1302.

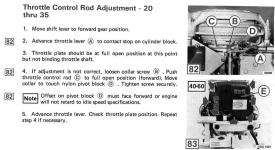

I am trying to set the "Throttle Pickup Adjustment" and "Throttle Control Rod Adjustment" according to the OMC manual. However, these settings seem to contradict each other. I really feel like I am missing something or misinterpreting the instructions.

For example:

Scenario 1, Throttle Pickup Adjustment

[1] I adjust the throttle control rod such that the carb begins to open just as the cam follower is between the two marks on the spark advance cam (this seems most important)

Since the throttle lever is not contacting the engine block when the carb reaches WOT, the carb continues to try to open past WOT and causes binding. Does the throttle lever need to rotate all the way to the engine block to advance WOT timing properly?

Cam follower leaves cam right between these marks as carb valve begins to open, and contacts the cam between the marks as it returns to the cam.

Throttle lever still has room to move before contacting engine block, so the butterfly valve tries to go past WOT in the carb.

Scenario 2, Throttle Control Rod Adjustment

[1] Advance throttle lever to stop against the engine block by hand (engine in forward gear)

[2] Manually open carb throttle valve to wide-open position (blade perfectly horizontal)

[2] Set throttle adjust collar screw against the nylon pivot block at this position

Then the cam follower comes down way too soon as I let off of the throttle. In other words as the cam follower comes down while the carb closes, it contacts the spark advance cam way to the left of the two marks where it is supposed to contact between as it comes down.

With carb butterfly valve held open, throttle lever is advanced by hand until it contacts the engine block. At this point the collar screw on the throttle control rod is set against the nylon pivot block. This results in carb opening to exactly WOT as tiller throttle handle is turned to WOT, pressing throttle lever against stop on engine.

When throttle is released, cam follower drops down and contacts cam well before the two marks

Not sure how I can have both of these conditions met at the same time. The engine will run when I set it to satisfy scenario #1, but I am afraid I am not advancing timing enough at WOT.

I hope this explanation makes sense.

All in all, the main questions I have are:

[1] When I turn the tiller throttle control to WOT, should the throttle lever stop against the engine block?

[2] Does the throttle lever need to be stopped against the engine block to fully advance the timing?

[3] **Is the cam follower supposed to leave/contact the cam between the two marks as the carb begins to open/close AND the throttle control rod be set such that the butterfly valve is at WOT with the throttle lever against the engine block? I do not see how this is physically possible on my engine.**

Tried to include all possible information.. I am continuing to research this and figure it out, as well as searching through this forum and others for any relevant information.

Thanks in advance for any info on this!!

I am referencing the OMC manual as well as Seloc manual 1302.

I am trying to set the "Throttle Pickup Adjustment" and "Throttle Control Rod Adjustment" according to the OMC manual. However, these settings seem to contradict each other. I really feel like I am missing something or misinterpreting the instructions.

For example:

Scenario 1, Throttle Pickup Adjustment

[1] I adjust the throttle control rod such that the carb begins to open just as the cam follower is between the two marks on the spark advance cam (this seems most important)

Since the throttle lever is not contacting the engine block when the carb reaches WOT, the carb continues to try to open past WOT and causes binding. Does the throttle lever need to rotate all the way to the engine block to advance WOT timing properly?

Cam follower leaves cam right between these marks as carb valve begins to open, and contacts the cam between the marks as it returns to the cam.

Throttle lever still has room to move before contacting engine block, so the butterfly valve tries to go past WOT in the carb.

Scenario 2, Throttle Control Rod Adjustment

[1] Advance throttle lever to stop against the engine block by hand (engine in forward gear)

[2] Manually open carb throttle valve to wide-open position (blade perfectly horizontal)

[2] Set throttle adjust collar screw against the nylon pivot block at this position

Then the cam follower comes down way too soon as I let off of the throttle. In other words as the cam follower comes down while the carb closes, it contacts the spark advance cam way to the left of the two marks where it is supposed to contact between as it comes down.

With carb butterfly valve held open, throttle lever is advanced by hand until it contacts the engine block. At this point the collar screw on the throttle control rod is set against the nylon pivot block. This results in carb opening to exactly WOT as tiller throttle handle is turned to WOT, pressing throttle lever against stop on engine.

When throttle is released, cam follower drops down and contacts cam well before the two marks

Not sure how I can have both of these conditions met at the same time. The engine will run when I set it to satisfy scenario #1, but I am afraid I am not advancing timing enough at WOT.

I hope this explanation makes sense.

All in all, the main questions I have are:

[1] When I turn the tiller throttle control to WOT, should the throttle lever stop against the engine block?

[2] Does the throttle lever need to be stopped against the engine block to fully advance the timing?

[3] **Is the cam follower supposed to leave/contact the cam between the two marks as the carb begins to open/close AND the throttle control rod be set such that the butterfly valve is at WOT with the throttle lever against the engine block? I do not see how this is physically possible on my engine.**

Tried to include all possible information.. I am continuing to research this and figure it out, as well as searching through this forum and others for any relevant information.

Thanks in advance for any info on this!!

Attachments

Last edited: