gm280

Supreme Mariner

- Joined

- Jun 26, 2011

- Messages

- 14,605

As some of you may know I am still working an entire boat, motor and trailer refurbishing package. I finished the OB and a trolling motor already. I'm posting this here in this section because even though it is part of a complete rebuild effort, it is really a project that can stand on its own. So if this is posted in the wrong section, the powers that be can move it if they think otherwise. It won't hurt my feelings.

Here is what I started with;

While on the surface it looks like it is fair condition, it is in serious need of some huge amounts of attention. The actual trailer tongue was cracked right where it attached to the chassis of the body of the trailer that I didn't know about when I bought it. So That started the entire rebuild project.

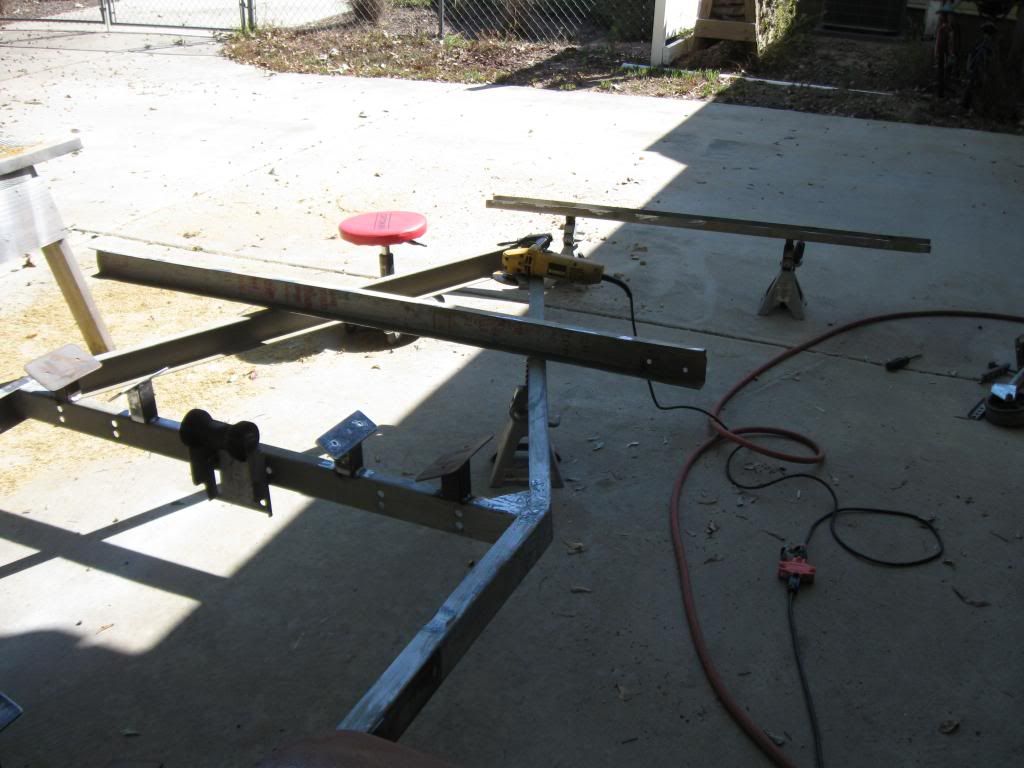

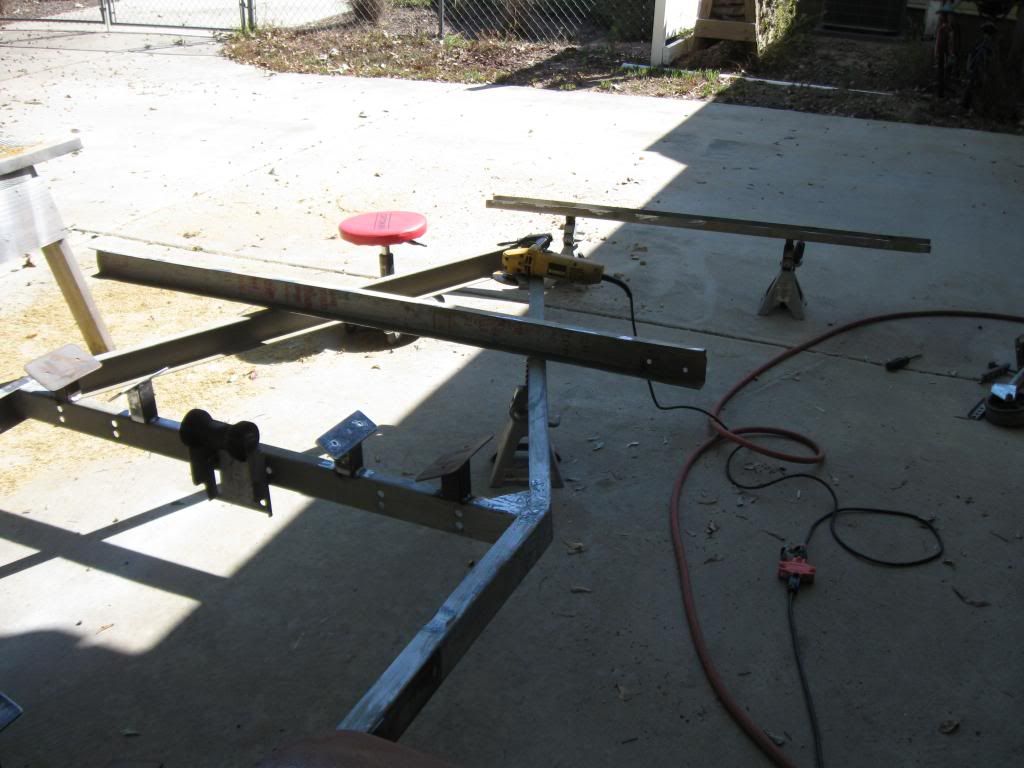

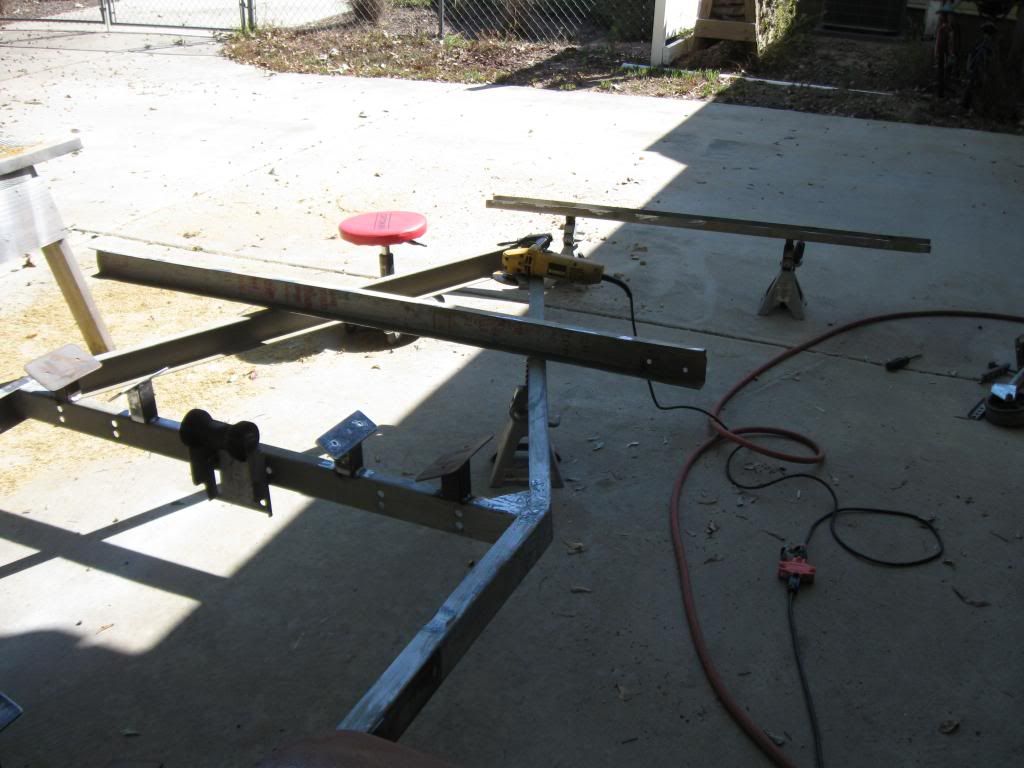

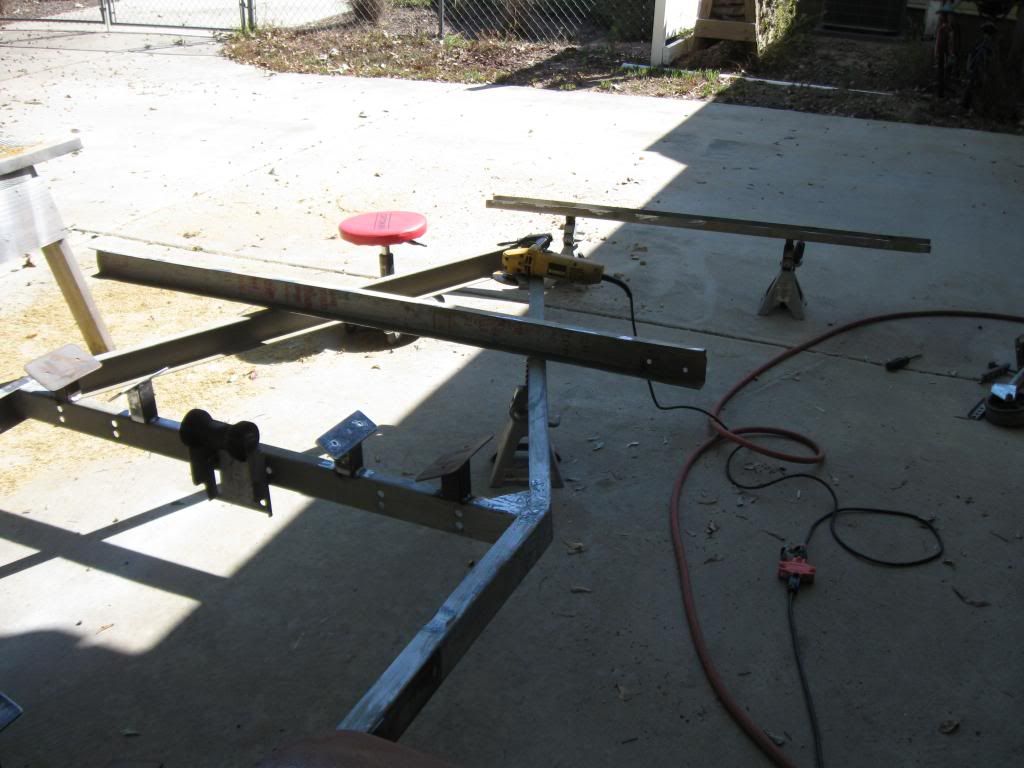

This was my starting point with everything stripped off the trailer

Not much to work with yet.

Luckily I have an engine host to use with lifting this around.

Here is the tongue removes after finding the crack.

Here is what I started with;

While on the surface it looks like it is fair condition, it is in serious need of some huge amounts of attention. The actual trailer tongue was cracked right where it attached to the chassis of the body of the trailer that I didn't know about when I bought it. So That started the entire rebuild project.

This was my starting point with everything stripped off the trailer

Not much to work with yet.

Luckily I have an engine host to use with lifting this around.

Here is the tongue removes after finding the crack.

Last edited: