Hello all,

I'm new here, thank you for the opportunity to join the community.

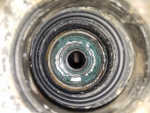

I have just nearly finished swapping out old for new longblocks on my twin Volvo Penta 5.7l engines, and getting ready to put them back in and realign them. One outdrive was very hard to remove, and turns out has a stuck and rusty gimbal (see pictures). I can't move the gimbal with my fingers, and there is a bunch of sand or corrosion dust in there. That driveshaft is also rusty, but still rotates great and articulates at the joints good too.

I'm assuming I will need to replace the gimbal, correct? Do I need to replace the bellows as well? What would you do to the driveshaft (just clean it up?)? Here is a picture of the bad gimbal, driveshaft, and also the seemingly healthy gimbal from the other drive that still spins like a top with fingers. Thank you very much in advance for any advice.

I'm new here, thank you for the opportunity to join the community.

I have just nearly finished swapping out old for new longblocks on my twin Volvo Penta 5.7l engines, and getting ready to put them back in and realign them. One outdrive was very hard to remove, and turns out has a stuck and rusty gimbal (see pictures). I can't move the gimbal with my fingers, and there is a bunch of sand or corrosion dust in there. That driveshaft is also rusty, but still rotates great and articulates at the joints good too.

I'm assuming I will need to replace the gimbal, correct? Do I need to replace the bellows as well? What would you do to the driveshaft (just clean it up?)? Here is a picture of the bad gimbal, driveshaft, and also the seemingly healthy gimbal from the other drive that still spins like a top with fingers. Thank you very much in advance for any advice.