holorinhal

Petty Officer 2nd Class

- Joined

- May 26, 2009

- Messages

- 119

i have a 1981 Merc 260( 5.7l 350cid) with a MC1 or Alpha drive. I upgraded fron the old cast iorn log exhaust to EMI Thunder center rise exhaust. i aslso changed the thermostat housing to a Sierra #18-3530-1.

i originally hooked every thing up , without a tstat to get the engine fired up, but the water temp was rising pretty quickly to above 200*.

I purchased a Tstat kit from the local marine shop. At first they gave me a 160* kit # 807252Q5 and it had a regular gasket for the intake to tstat housung fit. i ased them to give me the 140* kit, #807252Q4, because every thing i have read said that the 260 needs the 140 and that is what was in it before. the only difference is that the gasket in the 140 kit has two small holes on each side, of the bolt hole.

So my question is, before i install the $50 kit, is do i have the right one? What are the small holes in the gasket for, should i use the 140* or the 160* tstat?

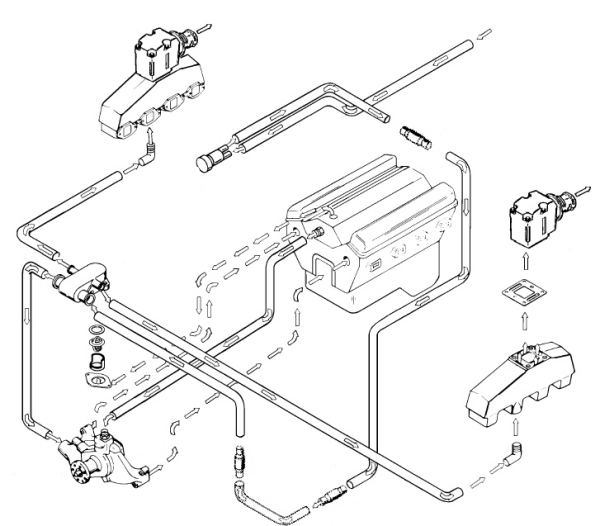

Here is a pic of My set up.

i originally hooked every thing up , without a tstat to get the engine fired up, but the water temp was rising pretty quickly to above 200*.

I purchased a Tstat kit from the local marine shop. At first they gave me a 160* kit # 807252Q5 and it had a regular gasket for the intake to tstat housung fit. i ased them to give me the 140* kit, #807252Q4, because every thing i have read said that the 260 needs the 140 and that is what was in it before. the only difference is that the gasket in the 140 kit has two small holes on each side, of the bolt hole.

So my question is, before i install the $50 kit, is do i have the right one? What are the small holes in the gasket for, should i use the 140* or the 160* tstat?

Here is a pic of My set up.