Lancer76

Petty Officer 2nd Class

- Joined

- Jul 23, 2017

- Messages

- 121

1976 mercruiser 233; Ford 351 with Rochester 2bbl carb. Engine starts easily and idles fine. Engine runs great at 35000 rpm for a few minutes and then the engine quickly looses power as if I pulled the throttle back. If I pull the throttle back quickly the engine will continue to run at low rpm, but if I don't throttle back; engine will die. If it dies, it starts immediately. No backfiring so I dont think its ignition. Seems like a fuel issue.

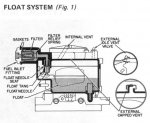

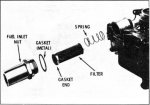

I cleaned fuel tank, replaced filter and fuel line from the tank to the filter. I still have to check the steel line from the pump to the carb. Any chance the carb float is adjusted too high so not opening the inlet valve enough? I did rebuild the carb last year so it's possible the float is maladjusted. Thoughts?

Thanks

I cleaned fuel tank, replaced filter and fuel line from the tank to the filter. I still have to check the steel line from the pump to the carb. Any chance the carb float is adjusted too high so not opening the inlet valve enough? I did rebuild the carb last year so it's possible the float is maladjusted. Thoughts?

Thanks