Samthomas33

Cadet

- Joined

- Aug 28, 2010

- Messages

- 8

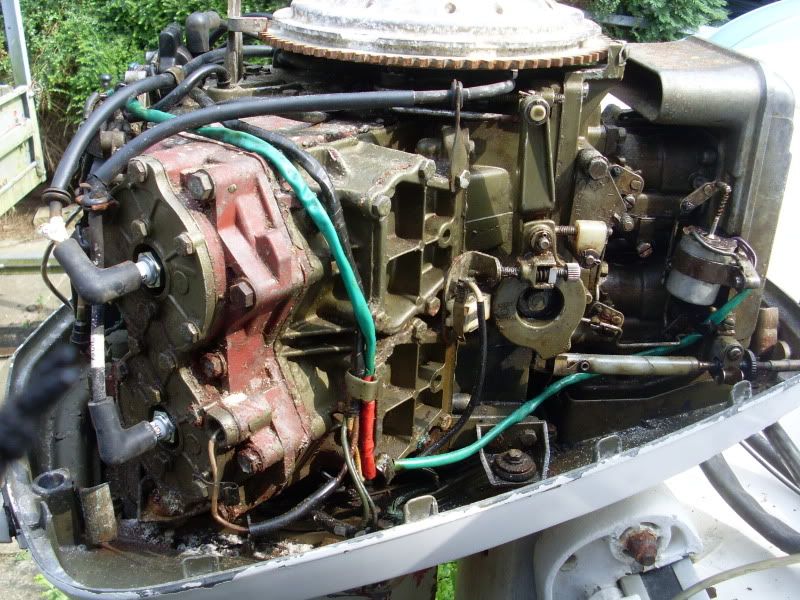

Hi all, this is my first post so hello to everyone! Right now my problem, I've got a 1972 85hp evinrude which we've had for about 7 year and in all this time it has never run properly. It takes for ever to start but once it goes it will start on the button after that, but then within half an hour/constant throttle it starts to bog down and miss fire, then won't start. If you feel the block after this only one side of it warm and the other bank is cold. So I'm assuming it only running on 2. Now one of the main problems is the points, you adjust them to the correct gap (which can any one confirm for me? As I'm just going from word of mouth) and then it runs great but when it starts to bog down you recheck the points and one of them has closed up! hense why it's running on 2! Now when I set the points I noticed that the lobe on the points assemble doesn't sit on the cam, so as the engine turns and the cam lobe comes around, it hits the points lobe and causes it to open, now I'm now sure if I'm right in saying this but isn't the points Lobe suppose to constantly be in contact with the cam?

Another problem it might be, is it worth me changing the coil and power pack? Or what do you think? And where the hell do I get spares for it as I can't find any anywhere, just the states!

I really do hope some one can help as 7 years of this is begining to get to me, I've been rescued more times than I care to remember!

Cheers every one and fingers crossed x!

Another problem it might be, is it worth me changing the coil and power pack? Or what do you think? And where the hell do I get spares for it as I can't find any anywhere, just the states!

I really do hope some one can help as 7 years of this is begining to get to me, I've been rescued more times than I care to remember!

Cheers every one and fingers crossed x!