- Joined

- Jul 23, 2011

- Messages

- 47,564

you could have used an 18" or 24" 1/4" drill bit extension and a set of leather gloves (acts as a bearing on the drill bit extension).

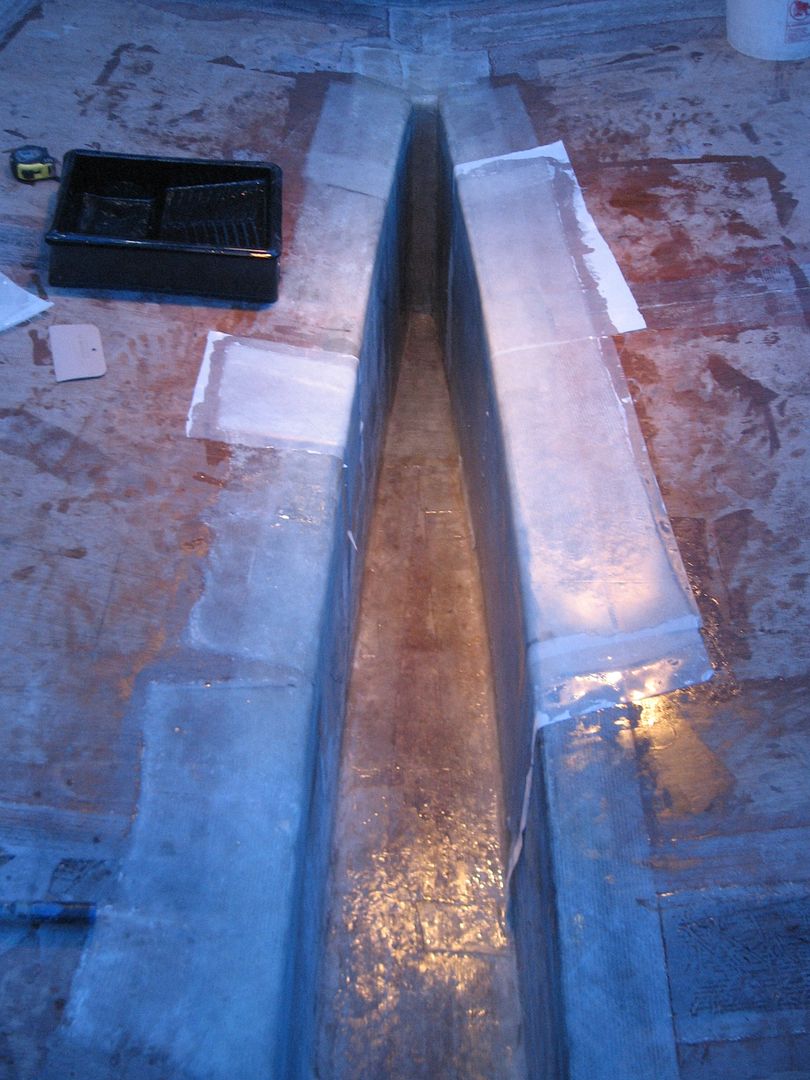

its rube goldberg, however may have allowed you to reach the bottom without having your head stuck in the keel.

its rube goldberg, however may have allowed you to reach the bottom without having your head stuck in the keel.