52FordF2

Petty Officer 1st Class

- Joined

- May 31, 2013

- Messages

- 372

If you need to change out the old shift cable to a new one here's a procedure

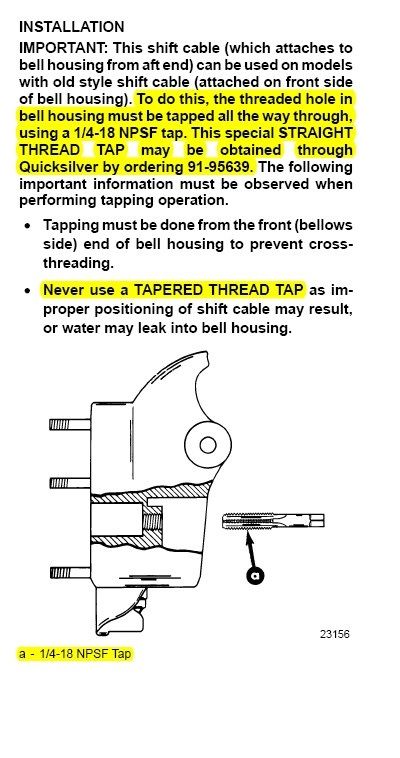

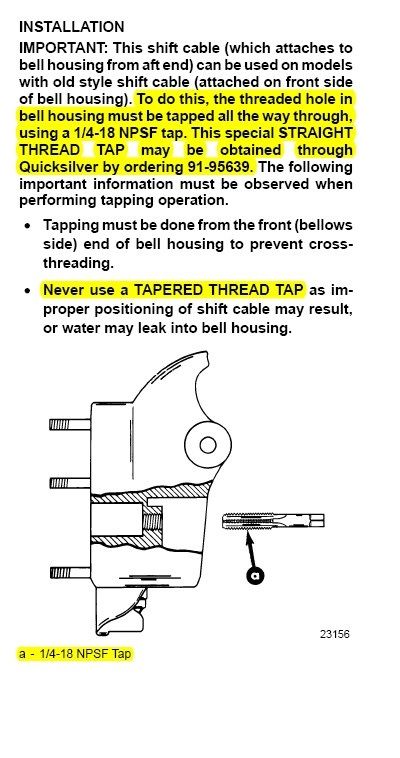

This is a National Pipe Straight thread tap NOT tapered.

Also NAPA sells a 9/16 Spark plug socket that you can use with a deep well to remove or tighten shift cable into bell housing. The Spark plug socket has the HEX on the backside that a deep well can slide onto and use with a ratchet wrench. This is a cheaper option instead of buying the more expensive installation tool.

This is a National Pipe Straight thread tap NOT tapered.

Also NAPA sells a 9/16 Spark plug socket that you can use with a deep well to remove or tighten shift cable into bell housing. The Spark plug socket has the HEX on the backside that a deep well can slide onto and use with a ratchet wrench. This is a cheaper option instead of buying the more expensive installation tool.