Goldie627

Lieutenant Junior Grade

- Joined

- Oct 28, 2013

- Messages

- 1,010

Thank you all!!! I appreciate all of you!!!

TP - yeah its kinda wierd but i think im getting the hang of looking up parts

Rick - 1708 is so nice to work with, it really contours it self to complex / compound shapes nicely. I think i was just a lil over ambitious on that seat spacer layup

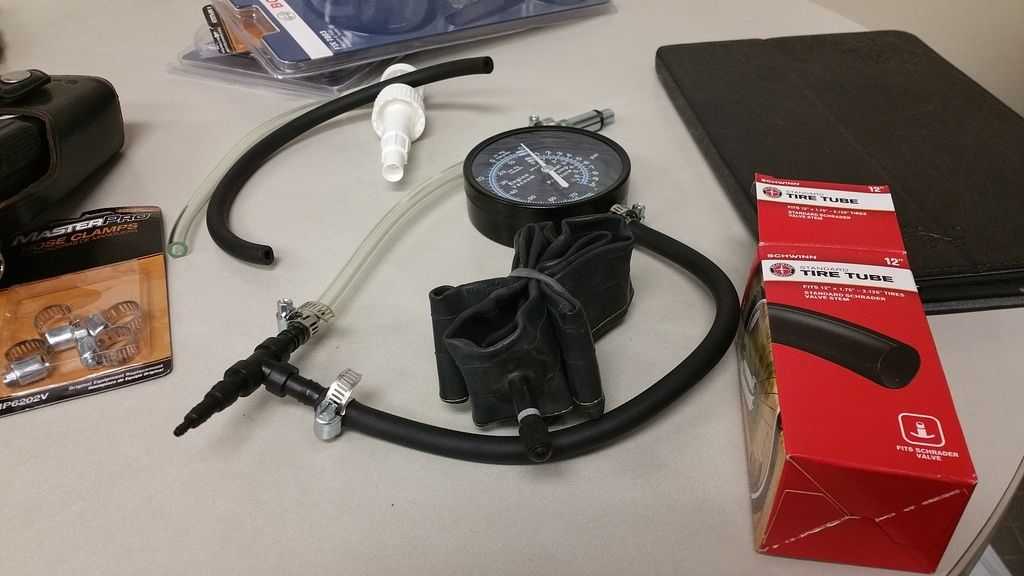

Plus as it wets out it stretches so that altered the amount of fabric that potentially gathered or grouped up after I flipped it over wet. It actually had contoured to the spacer like a dream when the cloth was dry. Another thing i could have done differently was to lay it up front to back instead of top to bottom. That way the air could have been easily pushed in that one direction. Im definitely going to be pressure testing this weekend! I called SEI today and you were spot on 106 with 1.94 gears

Saginaw - You're so right about taking things for granted and just going off the shops word.

Ja - Yep, this weekend i gotta start ordering some specialty tools, I need a hinge pin remover, engine alignment tool, gimbal bearing remover, I know theres more... I'll get a list going... I also need to make a list of parts... If i end up getting the SEI, im going to rebuild my alpha one gen 1, for the learning experience if nothing else

Supra - This weekend im gonna pressure test the outdrive, identify the leak, separate the upper from the lower, attempt to inspect the gears and shafts, etc... Im going to try to record as much as i can because Mark is going through the same situation I am. Hopefully some of the footage or parts/tools lists will be of some help. Im not sure how far ill get as i currently dont have any specaity tools for bearing removal and what not but atleast i'll get the ball rolling...

TP - yeah its kinda wierd but i think im getting the hang of looking up parts

Rick - 1708 is so nice to work with, it really contours it self to complex / compound shapes nicely. I think i was just a lil over ambitious on that seat spacer layup

Plus as it wets out it stretches so that altered the amount of fabric that potentially gathered or grouped up after I flipped it over wet. It actually had contoured to the spacer like a dream when the cloth was dry. Another thing i could have done differently was to lay it up front to back instead of top to bottom. That way the air could have been easily pushed in that one direction. Im definitely going to be pressure testing this weekend! I called SEI today and you were spot on 106 with 1.94 gears

Saginaw - You're so right about taking things for granted and just going off the shops word.

Ja - Yep, this weekend i gotta start ordering some specialty tools, I need a hinge pin remover, engine alignment tool, gimbal bearing remover, I know theres more... I'll get a list going... I also need to make a list of parts... If i end up getting the SEI, im going to rebuild my alpha one gen 1, for the learning experience if nothing else

Supra - This weekend im gonna pressure test the outdrive, identify the leak, separate the upper from the lower, attempt to inspect the gears and shafts, etc... Im going to try to record as much as i can because Mark is going through the same situation I am. Hopefully some of the footage or parts/tools lists will be of some help. Im not sure how far ill get as i currently dont have any specaity tools for bearing removal and what not but atleast i'll get the ball rolling...