archbuilder

Vice Admiral

- Joined

- Sep 12, 2009

- Messages

- 5,697

Man that milkshake oil almost wants to make you cry when you see it! Hopefully its something simple!

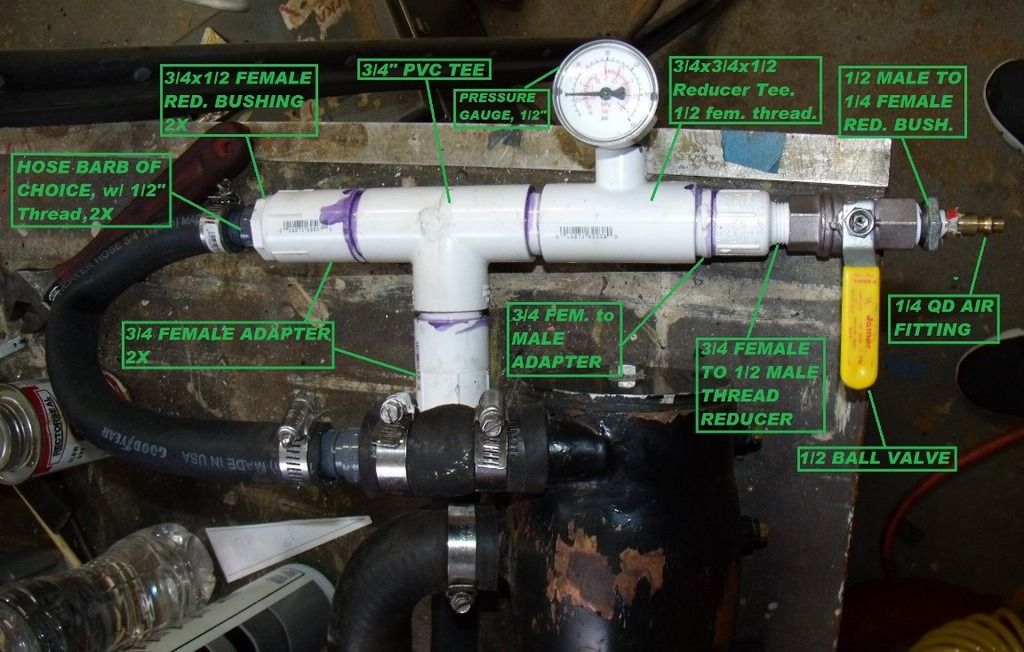

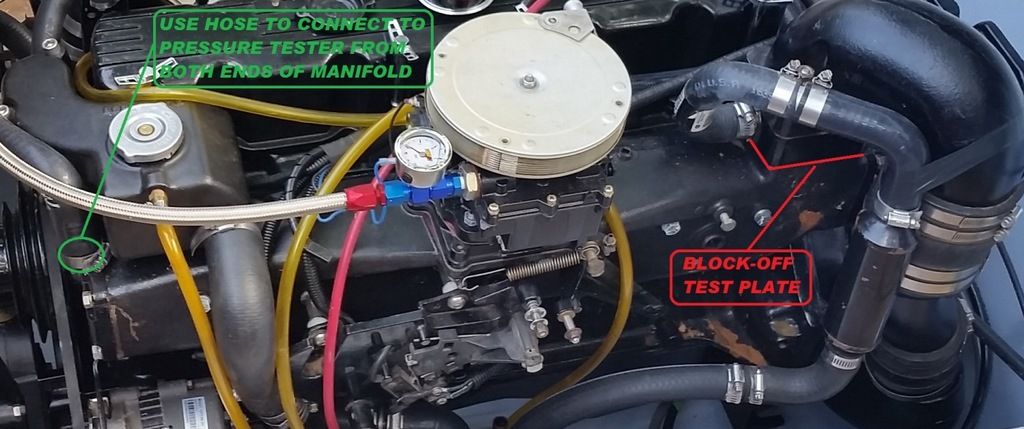

Thanks Woe, that looks easy enough. Fancy engine you got there and a fuel pressure gauge along with braided lines. Sweeeeet

Yep I haven't install the new electric Holley Red fuel pumps yet. I guess I have time now and with the starboard engine out it gives me room to install them. Trying to look on the bright side of this latest issue