Re: 1989 Cheetah 210es complete rebuild - project blood sweat & beers

Re: 1989 Cheetah 210es complete rebuild - project blood sweat & beers

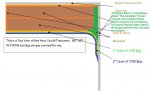

Make sure and take measurements of the width of the hull just incase it flexes during the rebuild. You need to get the cap back on. Giving quantity of materials estimates is tricky but for sure, to start you'll need 10 gals of 435 laminating resin, a 1lb of Cabosil, 1/2 lb of chopped fibers, bubble buster roller, 10 yds of 1.5 oz CSM and 10 yds of 1708 biaxial cloth. I have attached some drawings that should help you visulaize your tasks. friscoboaters videos should take care of the rest.

For sure that will get you started. You can look at doubling and some by the time you are done. 640 ounce for 5 gallons. most stringers are 8ft by at least 1 ft with tabbing. that is 8 sq feet. I mix my resin up at 3 liquid ounces per sq ft for 1.5 ounce csm and 1708. Alot of how to's say 3-4 onces, but I find 4 just way too much.This works for me because I hate needing a couple extra ounces on the end. If I have some left over I start something else. So 5 gallons will do about 4 stringers with a 1 ounce per sq ft of resin wet down . That is one wet out layer, one layer of csm then 2 layers of 1708 My stringers were 15 inches with tabbing so 5 gallons didn't go very far. It don't take long to eat up resin .

Also don't over catalyze because it will start to set up on you early and you will find you will end up with more micro bubbles then needed...give yourself time to work the layup

You will also find if you use your bubble buster lightly but fast action back and forth , let it do the work after getting rid of the bubbles etc it will bring the resin to the top. Don't use your bubble buster with alot of down force.That actually pushes away the resin and you end up with a dry spot. Play with it you will see the sweet spot

Good Luck

Cheers Jack