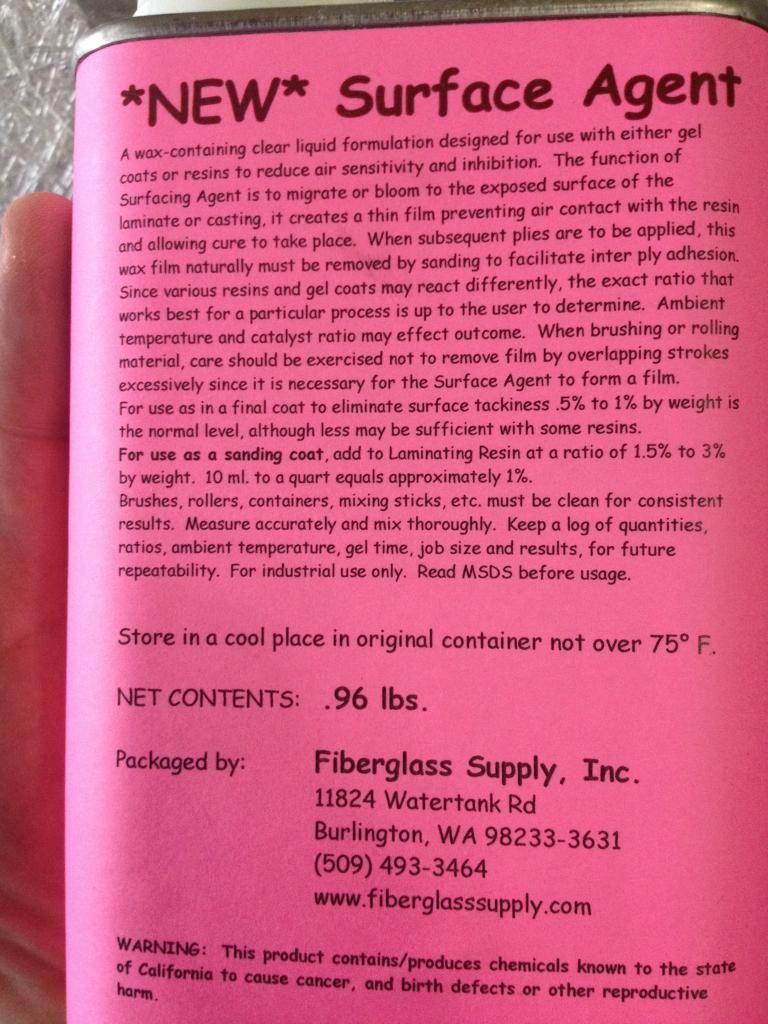

UHmmm, Not really, A full Layer of 1708 on the deck is not required IMHO. What you're looking for is mainly waterproofing the deck, binding the resin together to keep it from cracking and breaking and Strength in the attachment at the hull sides. CSM will do that. If you look at the illustration in the link the only 1708 is the 6" tabbing from the deck to the hull sides. I truly believe 2 layers of CSM is more than adequate for waterproofing the deck and I'd use wax in it so really ensure this. If you do wet on wet lams, and this should NOT be an issue when doing a deck since you can do big pours and on these big flat surfaces, you will have a really good deck that will stand up well to any conditions. You could make the 1708 tabbing a 8" -10" if you wanted but that's about all you'd need to change.