Daniel1947

Petty Officer 1st Class

- Joined

- Sep 22, 2010

- Messages

- 267

Re: 1982 Glastron Hpv165 bass boat restoration.

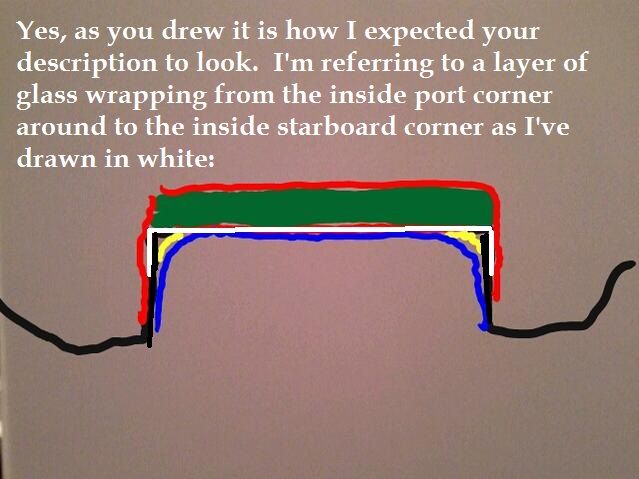

My 2 cents worth, and maybe not even worth that....The advice you are receiving from WOG and jbcurt is excellant. I think what you are missing here is that when your boat was manufactured, the beginning process was most likely GelCoat was sprayed (applied) to the inside of a large mold. Then layers of fiberglass cloth were applied, I don't know how many layers would have been applied, but this would have become bonded to the gelcoat and formed the basic shell of the boat. After the completion of the shell, it was at this point that the "wood" was attached. (The transom and stringers were then installed, tabbed in, etc.) This is what they are trying to get you to do. Build (repair) the outer shell first and make the hull all one piece before installing the wood. I am not going to have to do what you are doing as there have not been any prior repairs done to my boat. Until I drill some holes in the transom, I am not even sure I will have to replace it. I know the stringers and deck are shot. You have done great so far my friend, keep following sound advice and it will come out great.

My 2 cents worth, and maybe not even worth that....The advice you are receiving from WOG and jbcurt is excellant. I think what you are missing here is that when your boat was manufactured, the beginning process was most likely GelCoat was sprayed (applied) to the inside of a large mold. Then layers of fiberglass cloth were applied, I don't know how many layers would have been applied, but this would have become bonded to the gelcoat and formed the basic shell of the boat. After the completion of the shell, it was at this point that the "wood" was attached. (The transom and stringers were then installed, tabbed in, etc.) This is what they are trying to get you to do. Build (repair) the outer shell first and make the hull all one piece before installing the wood. I am not going to have to do what you are doing as there have not been any prior repairs done to my boat. Until I drill some holes in the transom, I am not even sure I will have to replace it. I know the stringers and deck are shot. You have done great so far my friend, keep following sound advice and it will come out great.