No Title

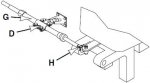

SCORE! I had completely removed the Fred Flintstone pulley and cable steering system with plans to upgrade to a modern rotary NFB single cable system. But my motor doesn't have a tilt tube to connect it to. Seastar/Teleflex makes a Transom or Splashwell mount mechanical steering connector to solve this problem. For an aluminum one they run around $175 - $200, and for stainless steel around $250. I stumbled across one, the COMPLETE KIT with tube and clevis, on closeout in Maine for $51 delivered to my door! And it's stainless steel! Just google if you need one, you'll need to register, then enter TEL-300611 in their serach box. And my new rubrail arrived! It is OEM in "taupe" color. They sold it in 10' increments only, and it appeared as if you got 10' individual pieces when you ordered. The original I removed was seamed on the gunwales, so I didn't worry about it. I ordered 5 10' sections - enough to do gunwales and freeboards. I received a 50' long continuous piece - SWEET!