Well, this was a pain. After doing a ton of research, getting advice from all of you, going back through my parts engine to figure out exactly how the water flows, and grasping at straws, I've finally figured out what is going on.

Based upon the symptoms, there were only so many reasonable possibilities of what could be happening. Once those reasonable possibilities were ruled out, I began to think about very rare, but theoretically possible, circumstances such as the t-stat housing having a mid-year design change and not being correct for my application. In the end, that wasn't a problem.

I tried to run a compression test to rule out a head gasket leak or a cracked cylinder, but I had a ton of trouble with the gauge not sealing properly. I eventually gave up on that. I'll comment on that in another thread because that seems to indicate another problem altogether. However, I really didn't think that the gaskets were an issue because I rebuilt this engine on a clean benchtop, using a proper torque wrench and following the proper procedures, including re-torqueing. Also, all parts were NOS or freshly machined and cleaned. This was my first rebuild, so it is possible that I messed up something with the gaskets, but I think that chances of that are quite small.

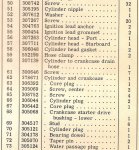

But even though I thought that the exhaust gaskets were ok, I needed to get in there to be sure. After opening it up, it was clear that the gaskets were fine. Also, the inner exhaust plate was clean and flat (it was NOS). However, something immediately jumped out at me. I love trivia (big fan of Jeopardy and Cash Cab) so I'll leave a picture trivia question for you: do you see what's wrong? I'm guessing that this is one of those theoretically possible, but very rare situations.