Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,924

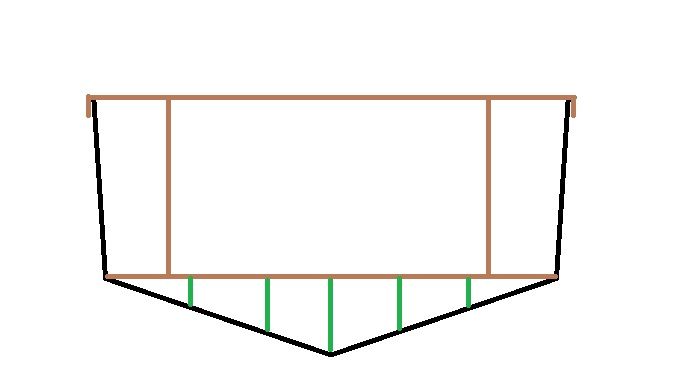

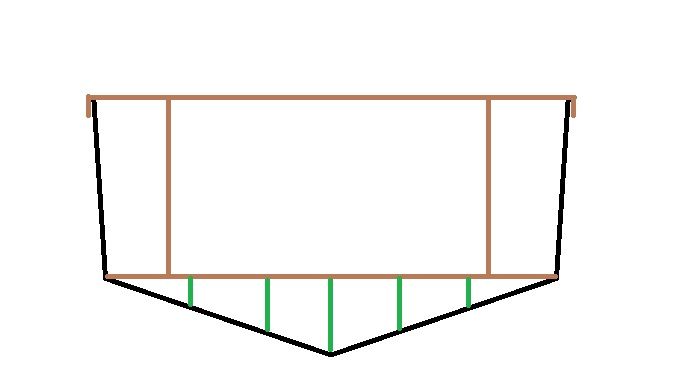

In another thread and many others as well, the question of how to obtain the proper stringer height came up. There are many ways of doing this. Being a 40+ year woodworker, I love to use Jigs whenever possible to make my work easier and repetitive and to increase accuracy. I like to keep things "Level and Plumb" as well. This can be challenging when working on boats when they are on a trailer or even on cradles trying to keep them level and plumb is difficult at best. After the input of several iBoats members on various methodologies and thinking quite a bit on the subject I came up with this jig. I've not put it to use yet, but I believe it should work quite well. Made from 2x2 material it would be hung from the sides of the hull at the time the stringers were being placed. Measurements would have been taken previously of the original stringer height and the jig made according to these calculations. Placing one jig at the stern and another towards the bow would allow you to create accurate cardboard or foam templates for your stringers and then during installation be assured they were all positioned, Port to Starboard at the correct height. Here's a drawing of the jig...

Hopefully it makes sense. If you moved one of the jigs from Back to front and measured from the bottom of the jig to 1/4" off the bottom of the hull approx. every 6 - 12" you could transfer these measurements to the Plywood Blank and should be able to get very close to the dimensions of the stringer. The jig should work whether the cap is Off or On. Once the deck is removed you would lay a 2x4 across the beam of the boat and measure down to the tops of the stringers to get the height required and record it. Build the jig to this measurement.

Again, I have never used this and am putting this out only as an idea that I think might be helpful. I will be trying this in the future when the need arises. If anyone in iBoats land cares to build one and try it, please post pics and your results. I would be very interested in your findings.

Just an

trying to be helpful!!!

trying to be helpful!!!

Hopefully it makes sense. If you moved one of the jigs from Back to front and measured from the bottom of the jig to 1/4" off the bottom of the hull approx. every 6 - 12" you could transfer these measurements to the Plywood Blank and should be able to get very close to the dimensions of the stringer. The jig should work whether the cap is Off or On. Once the deck is removed you would lay a 2x4 across the beam of the boat and measure down to the tops of the stringers to get the height required and record it. Build the jig to this measurement.

Again, I have never used this and am putting this out only as an idea that I think might be helpful. I will be trying this in the future when the need arises. If anyone in iBoats land cares to build one and try it, please post pics and your results. I would be very interested in your findings.

Just an

Last edited: