steelespike

Supreme Mariner

- Joined

- Apr 26, 2002

- Messages

- 19,069

Re: Restoring a Johnson CD-12, 1955 5-1/2

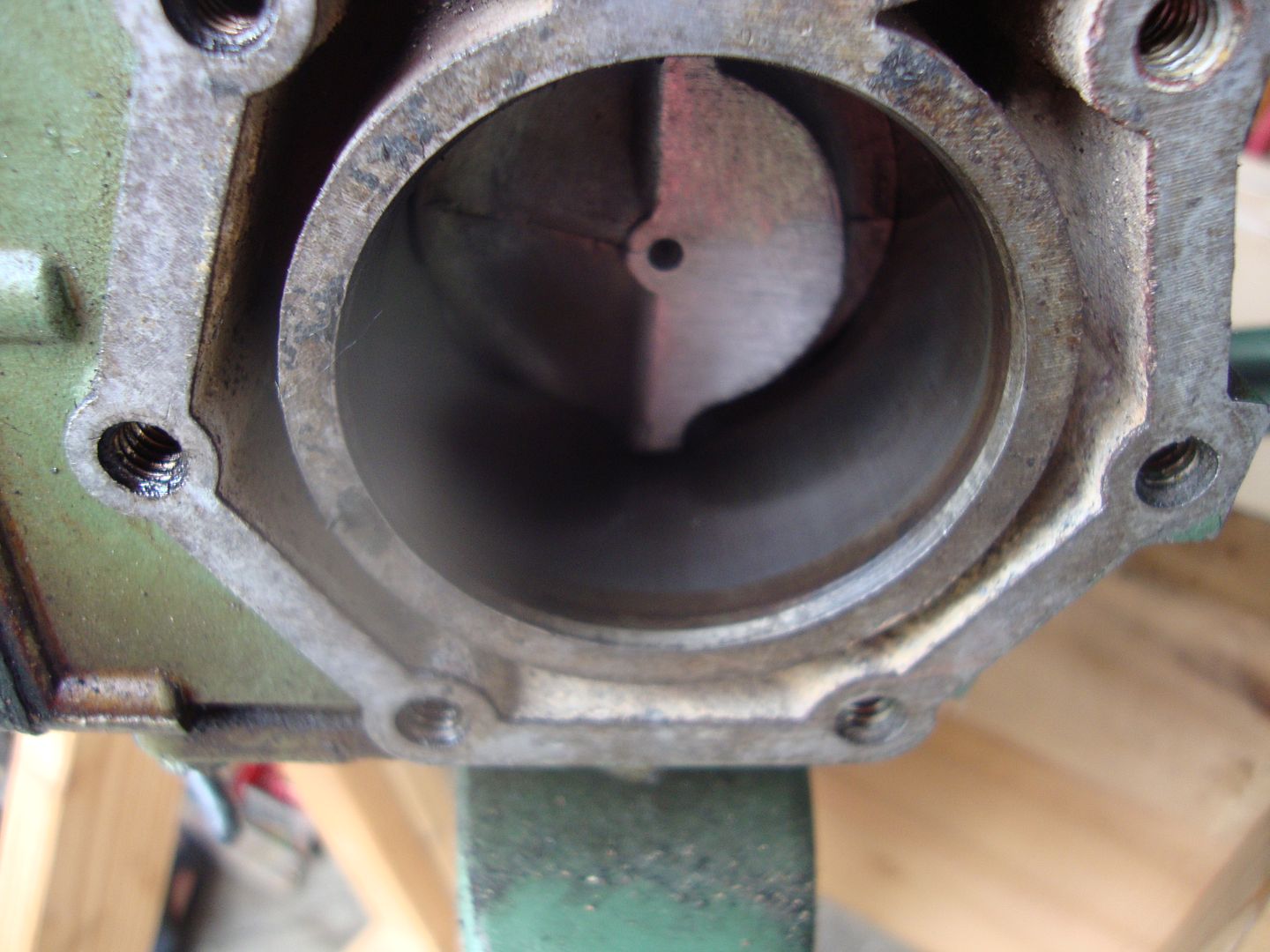

Sometimes the rings get carboned up and stick.A good decarb treatment with something like sea foam may free things up.

Just follow the directions.Also could be a head gasket.

Sometimes the rings get carboned up and stick.A good decarb treatment with something like sea foam may free things up.

Just follow the directions.Also could be a head gasket.