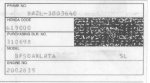

Can anyone tell me where to find the actual serial number on a 50HP Honda? I've got he frame number and model number, but I can't find the "serial number" anywhere. Here's the motor info:

And I'm trying to buy a part that is different depending on the engine serial number, but I can't find the numbers they mention anywhere:

And I'm trying to buy a part that is different depending on the engine serial number, but I can't find the numbers they mention anywhere: