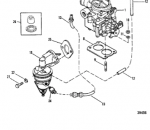

I have an 89 MerCruiser 3.7 that sat for a long time I’ve put quite a few posts up here to bring them back to life. So I decided to change the fuel pump thinking that diaphragm is got to be worn out why not. Well when I was installing the new one obviously.

I had tighten the bolts and when I went to tighten the left side I felt that she started to spin and I stopped immediately it was snug and I said oh boy let’s not spin this bolt. I have a few more weekends of summer to go and it’s been holding up but it’s going to be something I need to face. What is the best way to handle a stripped bolt by the fuel pump.

One thought was like we all do just go one size larger but I’m concerned about the threads and the shavings and all that stuff going into the crank case. My other thought was and I forget the name of that system where you drill it out you tap in a thread but once again my concern is metal bits going into the crank case when I go to drill it out. I will say this I am shocked that it was spinning I mean I’m the second owner of this boat prior to me the guy took it to the dealership all the timeI’m going to be winterizing it in about two weeks after I do that this is when I plan on attacking this or maybe next spring

I had tighten the bolts and when I went to tighten the left side I felt that she started to spin and I stopped immediately it was snug and I said oh boy let’s not spin this bolt. I have a few more weekends of summer to go and it’s been holding up but it’s going to be something I need to face. What is the best way to handle a stripped bolt by the fuel pump.

One thought was like we all do just go one size larger but I’m concerned about the threads and the shavings and all that stuff going into the crank case. My other thought was and I forget the name of that system where you drill it out you tap in a thread but once again my concern is metal bits going into the crank case when I go to drill it out. I will say this I am shocked that it was spinning I mean I’m the second owner of this boat prior to me the guy took it to the dealership all the timeI’m going to be winterizing it in about two weeks after I do that this is when I plan on attacking this or maybe next spring

Last edited: