It has been a while since I updated my thread, mostly because I have not done anything with the boat since last winter/spring. I was at the point of separating the boat 'halves' (hull & deck) and had run into a bit of a snag with a bond of fiberglass putty at the transom.

Well today, in a burst of energy, I managed to break the bond at the transom and now have the hull and deck separated.

I decided to put an access plate in the cockpit seat at the stern in order to gain access to the inside of the transom. I sized the hole for a SeaChoice 8" deck plate, which is available here on iBoats :thumb:

this gave me good access so that I could hammer in some chisels and wrecking bars into the putty to hopefully separate the bond.

Here is a picture of the putty from inside the transom area

The putty is not all that strong, so I was able to break the bond without hurting the outer fiberglass for the cockpit or transom.

Here is the stern area now separated and 'free'

Here are a couple of close ups of the putty areas

the hardware indentations are for the upper gudgeon.

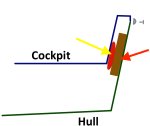

Here is the inside are of the transom with the cockpit now lifted up out of the way a bit.

I placed some boards/timbers between the halves of the boat so that I can get some straps underneath and lift the deck/cockpit assembly off.

My plan is to work the boat halves over the next few months and then re-assemble them as they do in the factory. Good news is that the foam seems to have dried out over the summer, so maybe I can just add a bit more in a few places and seal the chambers up so that they are air tight.