Eddie Rivera

Petty Officer 2nd Class

- Joined

- Feb 19, 2013

- Messages

- 183

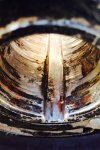

Need opinions and help on how to or whether I should repair a flywheel with a scratched bore. Please see attached pictures. Can I take it to a machine shop? I know I must have 80% contact from flywheel and shaft, can I use JB Weld to fill the scratches? Or make it straight and tight on the jetway? can I put some welding on it and just file afterwards?

It's my 1989 force 50 HP power head that I'm replacing with a 1991 power head. I had previously installed my flywheel key the wrong way and I damaged the key then I replaced the key and I found the new key with more damage, the motor was only on no more than five to ten minutes total but cranked many times.

I'll include a picture of the shaft the could have also contributed to the damage. I was beer able to leave the key on the shaft I would hold it in place with some anti seize cream. But the new power head has a clean shaft and key is held stuck in place. Much different.

Please advice!!!

It's my 1989 force 50 HP power head that I'm replacing with a 1991 power head. I had previously installed my flywheel key the wrong way and I damaged the key then I replaced the key and I found the new key with more damage, the motor was only on no more than five to ten minutes total but cranked many times.

I'll include a picture of the shaft the could have also contributed to the damage. I was beer able to leave the key on the shaft I would hold it in place with some anti seize cream. But the new power head has a clean shaft and key is held stuck in place. Much different.

Please advice!!!