Re: More transom problems, need some advice

Hello warnie100

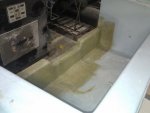

The problem I had in that picture was that when I pulled the old transom-core out I didn't support the hull good enough causing it all to bend inwards making the transom skin to warp inwards. I had to rise it a bit underneath to make it as strait as possible again.

The meaning of the 6kg's is that it took me 6kg of pb-mix to totally cover the transom-skin & the transom-core with a pretty thick layer that acts like a glue between the skin and the core. I mix my pb with talc instead of cabosil because of the ridiculous high price of cabosil/aerosil here in Sweden. The downside with talc is that it's a lot heavier and acts more "dead" when working with it.

I can't remember 100% but i will recall I used something like about 2 kg of talc to 4 kg of polyresins in that mix (looks like a 50/50 by size) and the widest putty knife I could found.

For this particular part of the job I did it like this, 1:st a really really good cleaning with 40grit angle-grinding (ruff and scuff) and then a lot of acetone to clean both surfaces, then i did a mix of 4 kg of polyresins, 12 tablespoons of 1/4" inch long chopped csm single fibers and only 1% hardener because it will cure faster when you have it all mixed. After the hardener is really well mixed in I add the talc until I have something that looks like peanut butter (pb) and then I used a tip from woodonglass here on the forum and did it pretty much as he told me.

"If she were mine I'd be troweling on some PB to smooth out that outer skin. Once it was smooth and hard, I would trowel the Peanut Butter onto the skin and the transom approximately 1/4" thick. this will yield 1/2" of PB use the clamps to apply Medium pressure, enuf for the PB to squeeze out around all the edges and fillet the edges. As for fabricating the transom, I'd put it back exactly like I found it."

Look at this video from friscoboater, It's how to mix the pb and what it's supposed to look like.

http://www.youtube.com/watch?v=N3kmr9ZctUo

I also used a stirring tool for cement that is attachable to a power drill to mix it because 6kg of this stuff will kill your arms if you don't looks like the "Hulk" and need a good workout.

I hope this will help you a bit.

My work will take all my time for now but I check out the forum as often as I can and I will answer you as soon as I can.

If I can't answer as fast as you like, I gets all my answers from this guys here on the forum - GT1000000, ondarvr, Oops!, Woodonglass. They are the pros for me and have done a tremendous job with all my questions. I usually don't recommend anyone to contact someone else without asking them but please do. They are the greatest. Also oops! have a really long thread that you should read. It will pretty much tell you all you need to know on how to build a boat.

http://forums.iboats.com/showthread.php?t=234392