The Force power

Commander

- Joined

- Feb 3, 2019

- Messages

- 2,258

IF the bores have not changed when "cleaning" the cylinder-walls, then yes.Understand, so I will assume that my rings are mislabeled then if I get real 39-817869A they should fit to my bores?

I would buy the piston you found on flEa-Bay & test this first

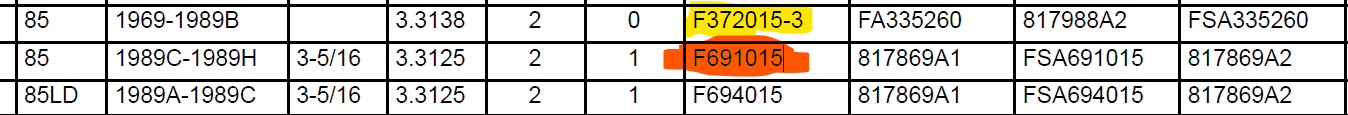

Verify with the piston/ring/bore chart