Re: MFG restoration

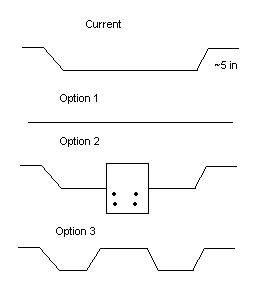

If your going to rebuild the transom, then I think option 1 (raising transom 5 inches) is the way to go. I would skip any sort of Sea Cast repair methods and go with a solid plywood transom. Make it laminated from two or more pieces of 3/4 or 1/2 or whatever it takes to match the original thickness. The new exposed 5" of top can be layered in glass until it is the same thickness as original. Sand, prime and paint. <br /><br />The trick will be fitting in the plywood core with the ends of the gunwale covering up 6 or 8" of the transom on each side. I don't know how your top is attached to the hull, but they are often difficult to separate.<br /><br />The other method to fitting the core is to cut out the entire inside of the transome fiberglass skin and insert the core that way, then replace the skin and glass over the seams. <br /><br />Other folks have done the core in multiple layers dropped in from the top and did a "scarf" cut on each layer. If the core is made from two 3/4" layers, the first is cut diagonally top left to bottom right, the second piece is cut the opposite . The drawback to this method is what a headache putting the pieces in with epoxy and glass cloth flopping all over then stuffing in the second layer with more epoxy and glass then hurry to arrange the pieces right and clamp it up snug before the epoxy sets.<br /><br />How about trading the Merc for a short shaft?<br /><br />Still, you could redo the transom to its original size/shape and get a simple jacking plate to raise up the motor ($100 - $300). Look at jack plates in the mega mall. They will offset the motor 4 to 6 or more inches depending on design.<br /><br />If it were my boat, I would cut the entire inside skin off flush to the hull, leaving the entire inside wide open. Then install a plywood core made from two 3/4" pieces of marine ply sealed in glass and epoxy. That gets epoxied in place. The skin can be epoxied back over it or left off and sand smoothe. The entire side and bottom edge of the plywood would be heavilly filled with epoxy puddy to create a large fillet. The fillet helps anchor the transom to the hull. I think this method is the most direct and easiest to accomplish because you have full access to the transom from the inside - no messing around trying to fit stuff in from above.<br /><br />I know this is long. Hope it helps.<br /><br />Mark.