toolsinbox

Petty Officer 2nd Class

- Joined

- Apr 22, 2009

- Messages

- 187

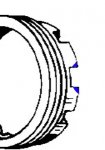

Quite some time ago I read your post with respect to the removal of the bearing retainer for Alpha drive and/or, trimming a few of the pieces to do the u-joints without taking off the retainer. As always your advice was spot on.

The part that has been driving me nuts for months now, was your reference to the retainer holding the o-ring while you install drive thus your point of trimming or brakeing off the teeth is not good.

I thought that you pushed the o-ring in place in the bell housing first. Or placed it on the drive up tite to the gasket flange on the drive.

Could you please clear up my missunderstanding of the install of this o-ring?

Thanks.

The part that has been driving me nuts for months now, was your reference to the retainer holding the o-ring while you install drive thus your point of trimming or brakeing off the teeth is not good.

I thought that you pushed the o-ring in place in the bell housing first. Or placed it on the drive up tite to the gasket flange on the drive.

Could you please clear up my missunderstanding of the install of this o-ring?

Thanks.