Hello Rick,

Just got through reading your ongoing restoration and I would love to come aboard and watch as you bring this nice looking boat back to better than new condition!

Everything you have done so far is first rate and definitely better that anything the factory ever could...

As to your question about tabbing in the transom.

Once you get a nice filet of PB all the way around, you can lay in some strips of 1708, approximately 6-8 inches wide all around the perimeter, then you can cut out the next big pieces of 1708 to completely cover the transom and extend at least a 2-4 inches further than the tabbing, 1708 lays much better than CSM and conforms to curves a lot better, just make sure it is thoroughly saturated with resin.

If absolutely necessary, you can make some relief cuts on the inside corners so it overlaps itself.

If you end up with any voids in the corners, just add another overlapping section as needed...

If you really feel the need, or just want to build up the keyhole thickness, you could add a second complete layer, overlapping the first one, again by 2-4 inches...

Probably not necessary, but you will have a battleship of a transom...

And, like I said, if you wet it out thoroughly, it will conform really well.

Use the chip brush to push the material into place, keep your catalyst on the low end of the scale and hustle...

Keep up the amazing progress and best of luck!

Gus

PS- I just realized you already did the PB filets...

When you wipe down the transom with acetone, make sure the filets feel sticky/tacky...that will insure that you get a good bond with the next layers...if they don't, you might have to give them a quick once over with some sandpaper to open up the pores a bit...

Also, be absolutely certain to pre-soak the bare transom wood with resin before applying the 1708...wait until it has soaked in and become tacky...if you don't do this, the dry wood could easily draw the resin from the 1708 and cause a weak bond...:tongue-new::tongue-new:

Another thing I learned was if you are going to have any overlaps (around corners or whatever) you need to wet out the bottom piece before you put the second piece over it. No amount of resin will soak thru two layers of 1708. See the white spot just under the tow hook support.

Another thing I learned was if you are going to have any overlaps (around corners or whatever) you need to wet out the bottom piece before you put the second piece over it. No amount of resin will soak thru two layers of 1708. See the white spot just under the tow hook support.

The last thing I "learned" is that there always seem to be some areas in 1708 that will not soak up the resin no matter what. Jay had a few spots where he had this happen. I even soaked the resin in a pan and a few spots that never saturated. I don't know what is up. Could it be manufacturing flaw, damage when shipping or handeling or is it sweat droplets contaminating the cloth? I had a couple of small areas that did this and a few strands that did the same thing. An example - the top has some dust on it so ignore, the middle is where I'm talking about and I swear they are not air bubbles even though it looks like it. There is one of the small problem spots off to the left. No matter what I did it would not take resin and go transparent. I even roughed it up with a box cutter, cutting the fibers then applied more resin, it would not soak it up; must be some kind of contamination?

The last thing I "learned" is that there always seem to be some areas in 1708 that will not soak up the resin no matter what. Jay had a few spots where he had this happen. I even soaked the resin in a pan and a few spots that never saturated. I don't know what is up. Could it be manufacturing flaw, damage when shipping or handeling or is it sweat droplets contaminating the cloth? I had a couple of small areas that did this and a few strands that did the same thing. An example - the top has some dust on it so ignore, the middle is where I'm talking about and I swear they are not air bubbles even though it looks like it. There is one of the small problem spots off to the left. No matter what I did it would not take resin and go transparent. I even roughed it up with a box cutter, cutting the fibers then applied more resin, it would not soak it up; must be some kind of contamination?

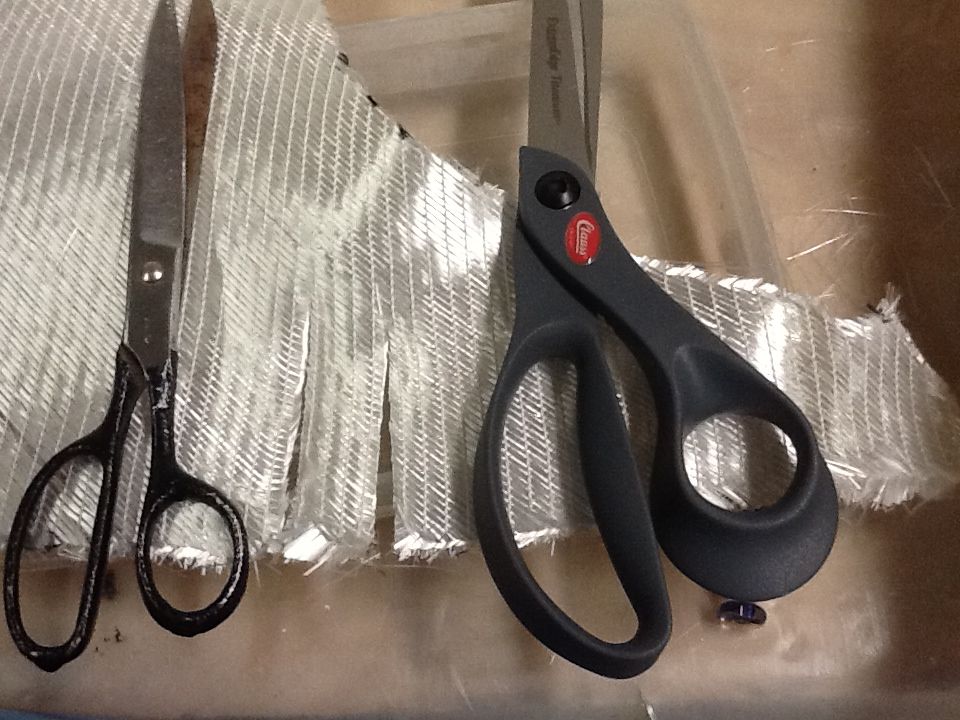

The hairy ends will be cut to length. Here is a closer view of how they turned out.

The hairy ends will be cut to length. Here is a closer view of how they turned out.

Finally, I got the second layer of 1708 across the transom. Looks like there is some white areas and bubbles but that us just the light reflecting. My thickest area at the top of the keyhole is right at 2" but the bottom is about 1.9". Within spec for parallelism but just a little thin. My two layers of 1708 added about 100 thousandths of an inch so I'd need two more layers of 1708 to get there at the thinnest area. I'm wondering if I could use some layers of gelcoat, inside to get the parallelism even closer, and it can be sanded flat and then put on more layer of 1708 to get the thickness correct. My transom, BTW, was only 1-7/8" originally. Just thinking out loud. Please let me know if you have any ideas on this. Here is the double tabbed and two layers of "skin" transom now.

Finally, I got the second layer of 1708 across the transom. Looks like there is some white areas and bubbles but that us just the light reflecting. My thickest area at the top of the keyhole is right at 2" but the bottom is about 1.9". Within spec for parallelism but just a little thin. My two layers of 1708 added about 100 thousandths of an inch so I'd need two more layers of 1708 to get there at the thinnest area. I'm wondering if I could use some layers of gelcoat, inside to get the parallelism even closer, and it can be sanded flat and then put on more layer of 1708 to get the thickness correct. My transom, BTW, was only 1-7/8" originally. Just thinking out loud. Please let me know if you have any ideas on this. Here is the double tabbed and two layers of "skin" transom now.

I paid about $5 for these furniture stripping gloves, just wish I'd had them all along for cleaning brushes, pails, bubble buster.

I paid about $5 for these furniture stripping gloves, just wish I'd had them all along for cleaning brushes, pails, bubble buster.