Re: 89 Four Winns Freedom 170 Floor / Stringer Rebuild PICS

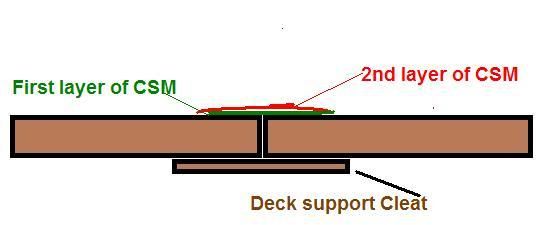

I thought I would post a few pics of my fiberglass progress on the stringers. It's definitely coming along. If it weren't for my real job, I could get more done. Lol. If that was the case, then this would be my job. Well I haven't glassed the wooden deck mounting blocks yet, but I've just about gotten all layers of glass over the stringers. I started with the csm, then went to the woven, then finishing up with csm again to smooth it out.

It's kinda hard for me to tell which layer I'm on in these pics, but it's really just so you can see.

Here

I think I'm at various stages in these pics. I did stringers, then bulkheads, then stringers again. So one pic might have just csm on the bulkheads, while the stringers have csm and the layer of woven. I'm pretty happy with the results so far. I'll try and post afew more pics tomorrow. Let me know what y'all think.

Matt

I thought I would post a few pics of my fiberglass progress on the stringers. It's definitely coming along. If it weren't for my real job, I could get more done. Lol. If that was the case, then this would be my job. Well I haven't glassed the wooden deck mounting blocks yet, but I've just about gotten all layers of glass over the stringers. I started with the csm, then went to the woven, then finishing up with csm again to smooth it out.

It's kinda hard for me to tell which layer I'm on in these pics, but it's really just so you can see.

Here

I think I'm at various stages in these pics. I did stringers, then bulkheads, then stringers again. So one pic might have just csm on the bulkheads, while the stringers have csm and the layer of woven. I'm pretty happy with the results so far. I'll try and post afew more pics tomorrow. Let me know what y'all think.

Matt