Re: 89 Four Winns Freedom 170 Floor / Stringer Rebuild PICS

Well,i ordered the nida bond today. Shipping is outrageous!!! 147$ a pail for product and 40$ to ship, plus 25$ for hazardous chemical shipping that ups charges!!!! +++ tax... so it cost roughly 225$ Its worth it, to know that that my stringers are going to be made of something non rottable.

+++ tax... so it cost roughly 225$ Its worth it, to know that that my stringers are going to be made of something non rottable.

So far ive ordered 5gallons of 435 resins, 5yards of csm, 1 quart of gelcoat, 5 gallons of nida bond, and 3 sheets of marine plywood. Looking at roughly 675$ worth of product and shipping costs for those of you interested.

Ordered csm, gel coat, and resin from uscomposites. Nida bond from apdmro.com. and plywood locally.........

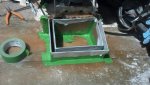

Heres a couple more pics of post sanding

Closer each day!!

Matt

Well,i ordered the nida bond today. Shipping is outrageous!!! 147$ a pail for product and 40$ to ship, plus 25$ for hazardous chemical shipping that ups charges!!!!

So far ive ordered 5gallons of 435 resins, 5yards of csm, 1 quart of gelcoat, 5 gallons of nida bond, and 3 sheets of marine plywood. Looking at roughly 675$ worth of product and shipping costs for those of you interested.

Ordered csm, gel coat, and resin from uscomposites. Nida bond from apdmro.com. and plywood locally.........

Heres a couple more pics of post sanding

Closer each day!!

Matt