Not sure if this will work on the cone clutch drive, but on my OMC Cobra what I have found helpful is to use a long thin screwdriver to turn the u-joints to get the driveshaft splines to line up, as long as the driveshaft is centered and entering the coupler that will help it to slide on. The Cobra is installed in neutral, I don't know about the cone clutch drive, though. If it gets installed in gear, you can try turning the prop, I have found that all it takes is just a tiny movement of the driveshaft to get the splines to line up. Kind of like installing a manual trans after a clutch job.

First though, do you have an alignment tool? this is very useful to check alignment and also to get the gimble bearing aligned with the way the driveshaft needs to enter it.

I do that first, then slide the drive in most of the way, then slide the long thin screwdriver in the u joints so I can turn them if needed.

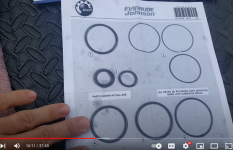

View attachment 396328

you can see the screwdriver on the ground

the drive jack is great for making this easy on your back

I've had this one about 15 or so years.