fuzzeywiggler

Petty Officer 1st Class

- Joined

- Feb 17, 2008

- Messages

- 357

Well its been a few years since any major work and now it's boat repair season and it looks like a long one.

I've been going at it for the past month and I think it's time to re-start this thread.

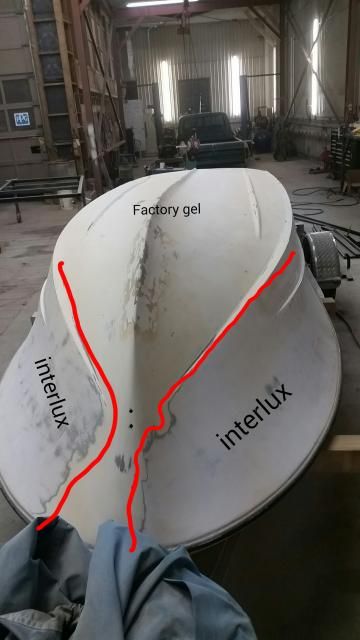

My choice of interlux marine paint really dissapointed me. I kept it in the water for a couple weeks over the last few years and got a lot of real bad blisters.

I started by flipping the boat on the trailer

Lots of blisters

I stripped all the paint and primer lots of hand work here.

I've been going at it for the past month and I think it's time to re-start this thread.

My choice of interlux marine paint really dissapointed me. I kept it in the water for a couple weeks over the last few years and got a lot of real bad blisters.

I started by flipping the boat on the trailer

Lots of blisters

I stripped all the paint and primer lots of hand work here.