jrttoday

Lieutenant Junior Grade

- Joined

- Feb 8, 2010

- Messages

- 1,081

GAS GAS GAS!!!

did you know that the most likely reason for the back glass being blown out in vehicles is the Bean Burrito from Taco Bell? :hungry::hungry::llama::lol:

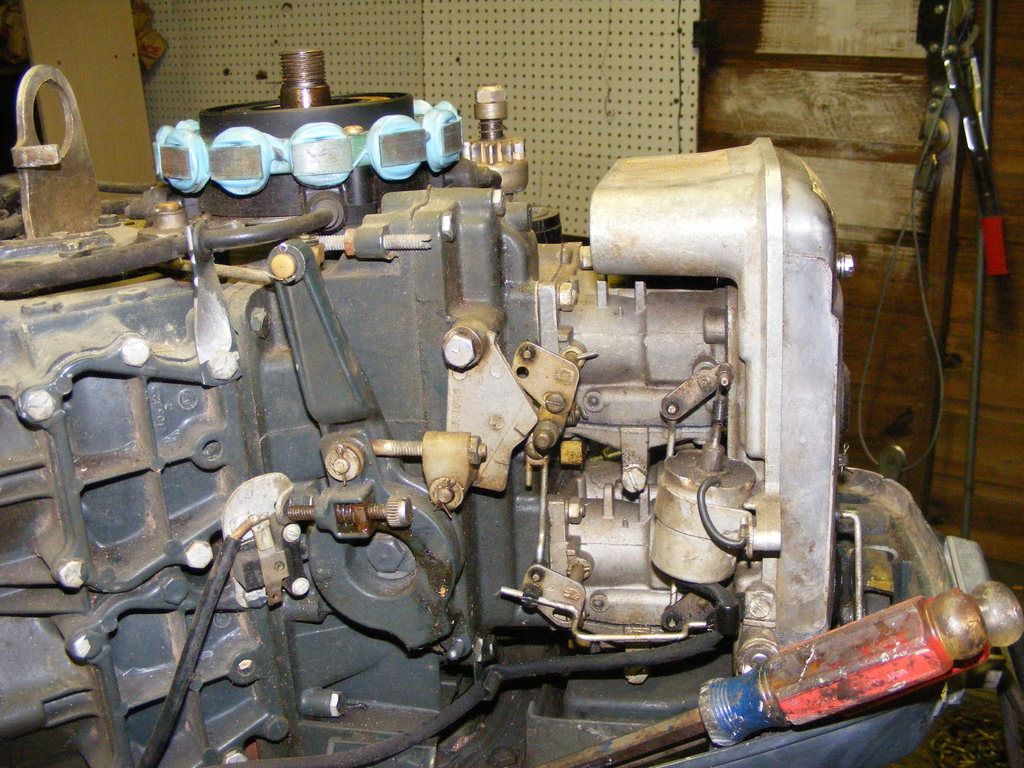

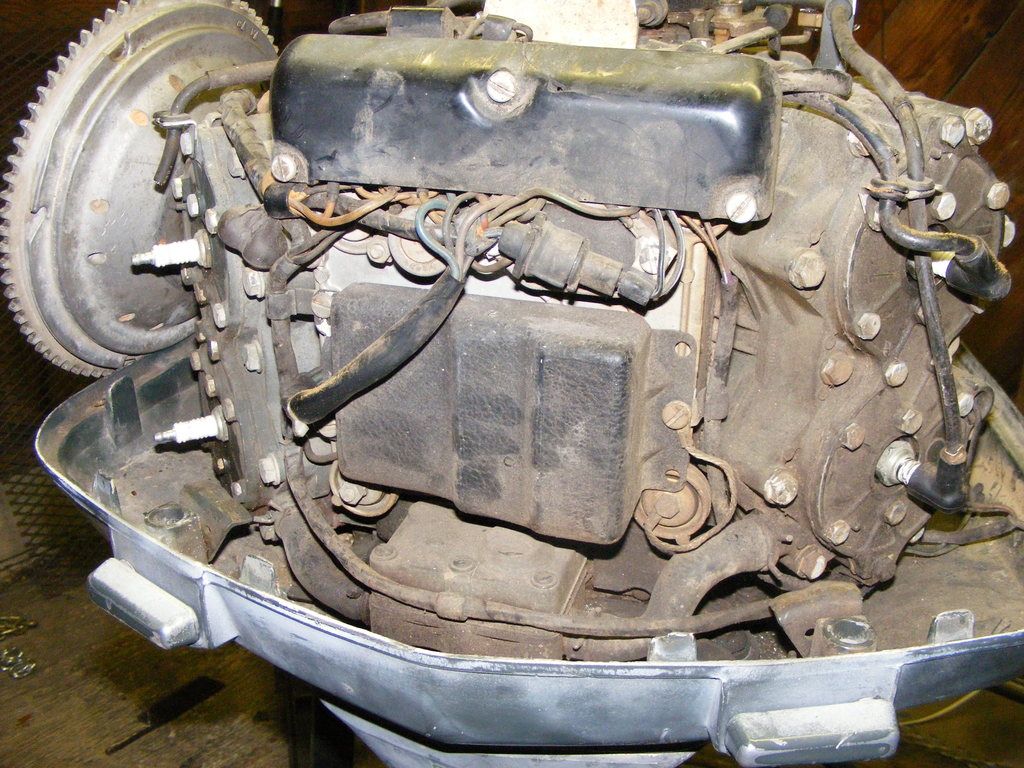

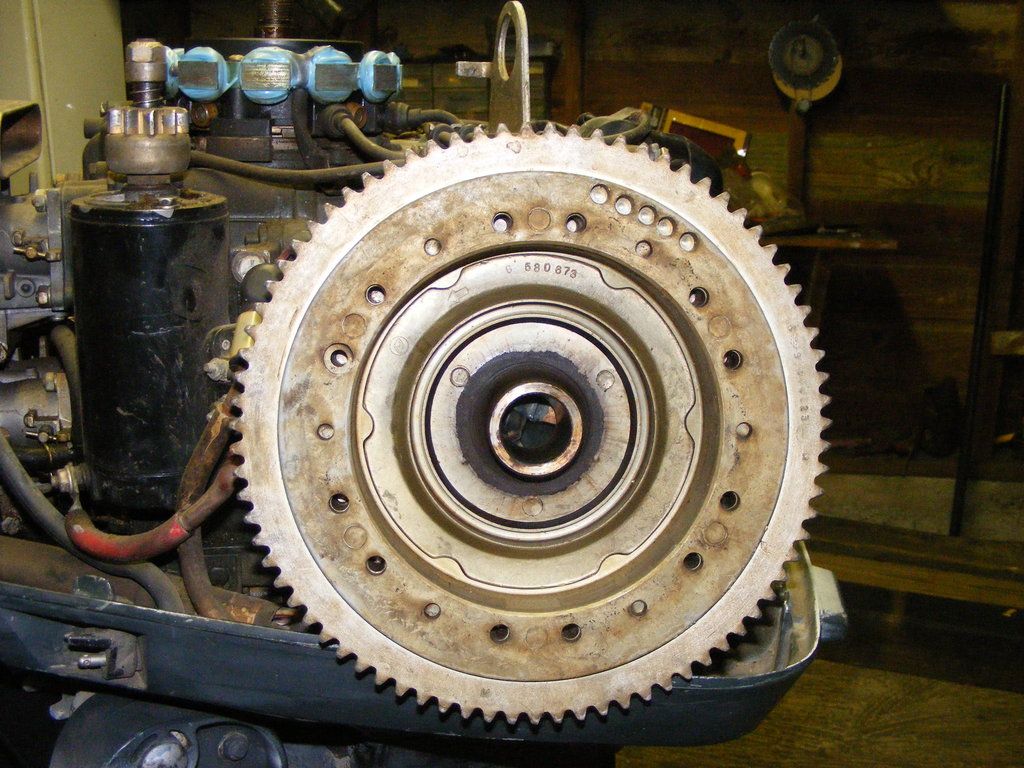

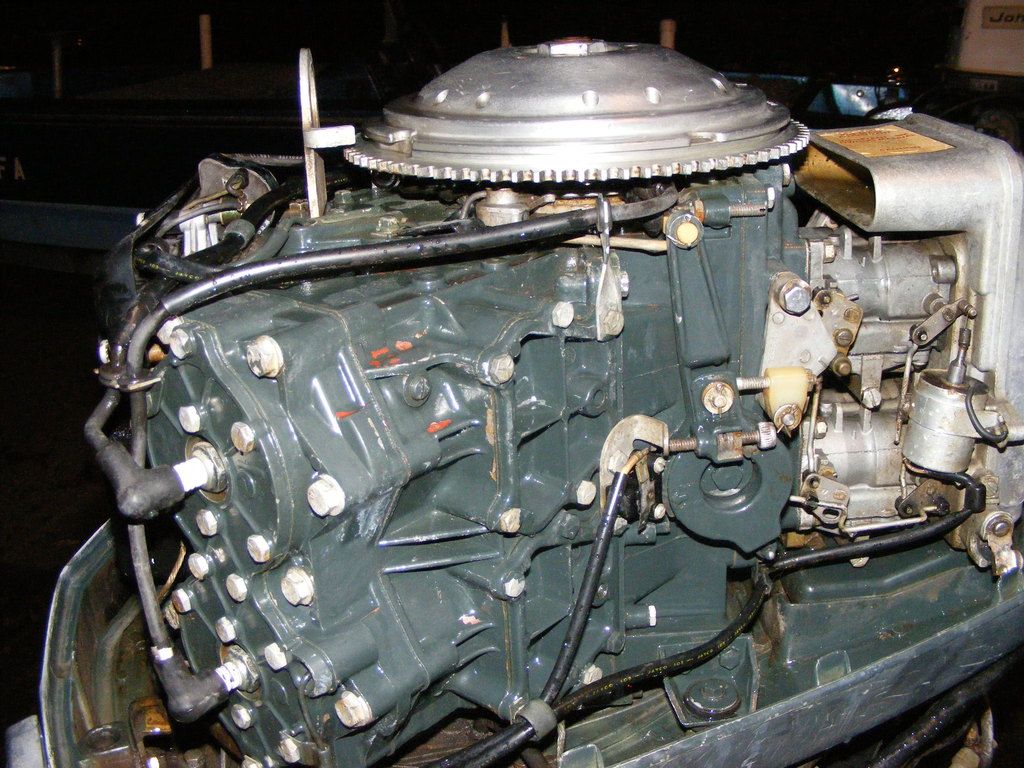

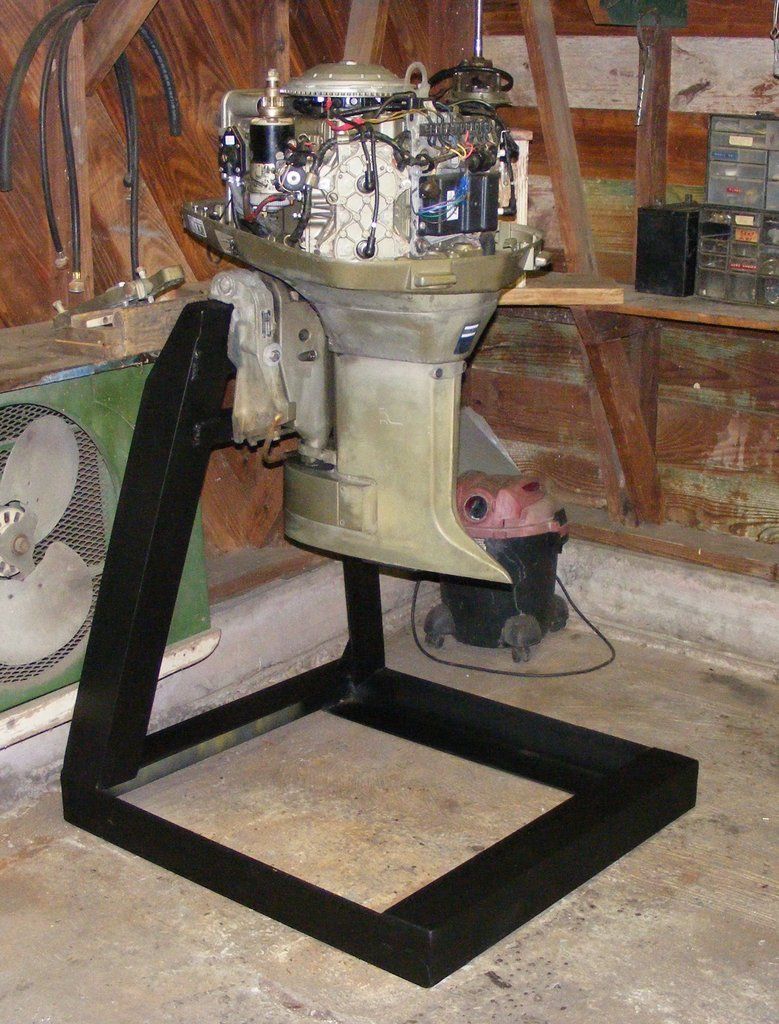

Am a couple days/weeks lol from beginning to work on this old motor and the question of octane/compression ratio came up.

This is what I found online "18. I have an older outboard with higher compression. Should I burn PREMIUM gas?

NO! Here's why. The octane ratings are composed of 2 components, research octane and motor octane (RXM/2) divided by 2. The RESEARCH octane is the quality of the base stock, the MOTOR octane is derived from additives. The oil company will never tell you the ratios. Problem is the highest octanes are achieved by MOTOR octane additives, which will just gum up the pistons in a 2 cycle engine. Base stock is generally the same. The MID-GRADE gas has the detergent additives needed to clean your motor and sufficient octane for MOST motors. If you have a MERCURY, FORCE or OMC motor from the early 70's thru mid-80's refer to technical bulletins from the manufacturers for timing changes and replacement head gaskets to lower compression to use today's gasoline's."

Am considering head gasket replacement, but also where would I find these technical bulletins?

and any experience with octane boosters and corn free gas or otherwise?

did you know that the most likely reason for the back glass being blown out in vehicles is the Bean Burrito from Taco Bell? :hungry::hungry::llama::lol:

Am a couple days/weeks lol from beginning to work on this old motor and the question of octane/compression ratio came up.

This is what I found online "18. I have an older outboard with higher compression. Should I burn PREMIUM gas?

NO! Here's why. The octane ratings are composed of 2 components, research octane and motor octane (RXM/2) divided by 2. The RESEARCH octane is the quality of the base stock, the MOTOR octane is derived from additives. The oil company will never tell you the ratios. Problem is the highest octanes are achieved by MOTOR octane additives, which will just gum up the pistons in a 2 cycle engine. Base stock is generally the same. The MID-GRADE gas has the detergent additives needed to clean your motor and sufficient octane for MOST motors. If you have a MERCURY, FORCE or OMC motor from the early 70's thru mid-80's refer to technical bulletins from the manufacturers for timing changes and replacement head gaskets to lower compression to use today's gasoline's."

Am considering head gasket replacement, but also where would I find these technical bulletins?

and any experience with octane boosters and corn free gas or otherwise?