This is a very detailed question so it may be a bit confusing referring to all of the attached photos and the drawing.

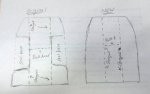

I am in the process of putting in a new deck in my 14' Bayliner Capri. I have removed the old deck and seat bases along with the foam for the seat bases and in the stern. What I expected when I started this was for the deck to go under the seat bases but that is not the case. In the drawing I did, you can see that the deck in the "original" diagram has a capital "I" shape. Basically, narrow in the middle and wide at the ends. It does not go under the seat bases. It is also split in halves at the bulk head. The seat bases actually had foam built up very high to the 4" height above the deck and had 1/2" plywood surrounding the edges (See photos of seat bases).

NOW, I wanted to make my new deck like the 2nd drawing labeled "NEW." That is what I thought the original deck would be like.

My question is, can I do this or do I have to make it like the original one? My main concern is the new seat bases.

Do I have to have the foam going that high or can I just place new foam under the bases and have a hollow seat base box built on top? In the photo showing the deck completely removed, with gas tank showing, you can see that there was no foam under the center area in front of the gas tank. This leads me to believe that I may need that extra foam that was part of the seat base. Can I just put that extra foam somewhere else (such as in front of bulk head) to make up for it? Or…do I even need that extra foam?

If I have to make the new deck just like the original, it seems a bit complicated with the seat bases so any help is highly appreciated. Thanks!

I am in the process of putting in a new deck in my 14' Bayliner Capri. I have removed the old deck and seat bases along with the foam for the seat bases and in the stern. What I expected when I started this was for the deck to go under the seat bases but that is not the case. In the drawing I did, you can see that the deck in the "original" diagram has a capital "I" shape. Basically, narrow in the middle and wide at the ends. It does not go under the seat bases. It is also split in halves at the bulk head. The seat bases actually had foam built up very high to the 4" height above the deck and had 1/2" plywood surrounding the edges (See photos of seat bases).

NOW, I wanted to make my new deck like the 2nd drawing labeled "NEW." That is what I thought the original deck would be like.

My question is, can I do this or do I have to make it like the original one? My main concern is the new seat bases.

Do I have to have the foam going that high or can I just place new foam under the bases and have a hollow seat base box built on top? In the photo showing the deck completely removed, with gas tank showing, you can see that there was no foam under the center area in front of the gas tank. This leads me to believe that I may need that extra foam that was part of the seat base. Can I just put that extra foam somewhere else (such as in front of bulk head) to make up for it? Or…do I even need that extra foam?

If I have to make the new deck just like the original, it seems a bit complicated with the seat bases so any help is highly appreciated. Thanks!

Attachments

Last edited: