Captndrydock

Seaman

- Joined

- Mar 9, 2020

- Messages

- 57

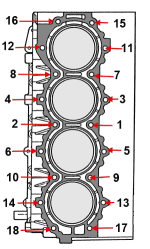

I was recently advised to re torque the head bolts on my 77 135 hp Chrysler outboard twice a year. My concern is whether they are torque to yield bolts or normal bolts? I'll probably leave well enough alone, but still curious if this is standard preventive maintenance on these motors.