markhodges78

Chief Petty Officer

- Joined

- Aug 4, 2016

- Messages

- 416

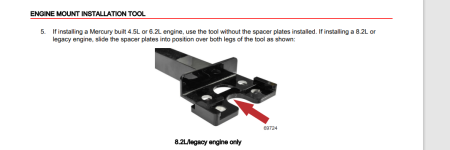

So I bought an engine mount installation tool.. I got it used after receiving the tool and looking up at the instructions for the tool it seems that I need spacers that come with the tool but when looking the tool up there is no mention of the spacers at all does anyone have any experience with this tool.. part number 806794A02 and instruction sheet below

Thanks Mark

Thanks Mark