Chris51280

Ensign

- Joined

- Jan 24, 2018

- Messages

- 928

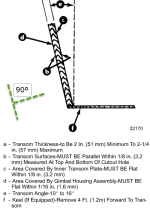

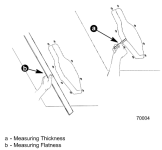

if you look at the bolts, it's perpendicular to the transom face. Many used drilling jigs. If you have a drill press, you can drill a hole into a block of wood and use that to guide the drill. since you already have the holes in the fiberglass, use that as a locator. the holes are bigger so it allows some clearance for the assembly to be fitted on. I also coated the inside of the holes with resin to seal.